In this tutorial, we will focus on how to Integrate the CNC Gateway with New Generation CNC. We hope this proves helpful.

In the previous lessons, we covered :

How the EG8200 Mini CNC Gateway interfaces with Siemens CNC systems

How to Integrate the CNC Gateway with Mitsubishi CNC

This lesson will provide a detailed explanation for New Generation CNC systems.

1. EG8200 Mini CNC Gateway

En EG8200 Mini CNC Gateway is a data acquisition gateway specifically designed for CNC machine tools, featuring robust data collection and remote monitoring capabilities. This device supports multiple industrial protocols including Modbus and MQTT, is compatible with CNC machine tools from various brands, and empowers users to achieve remote management of their machine tools.

2. New Generation CNC

Syntec Technology Co., Ltd., established in 1995 and headquartered in Taiwan, is a company specializing in the R&D and manufacturing of PC-based CNC systems.

Focusing on the machine tool sector, the company’s product portfolio includes turning and milling machine controllers, industrial machinery controllers, servo drives, motors, encoders, and other servo products, while also providing one-stop automation solutions.

In recent years, Syntec has actively expanded into smart manufacturing, launching its “Next Generation CNC” series. This series integrates cloud management, intelligent debugging, and equipment diagnostics to meet modern manufacturing demands for efficiency, intelligence, and reliability.

3. How to Interface the EG8200Mini-CNC gateway with New Generation CNC

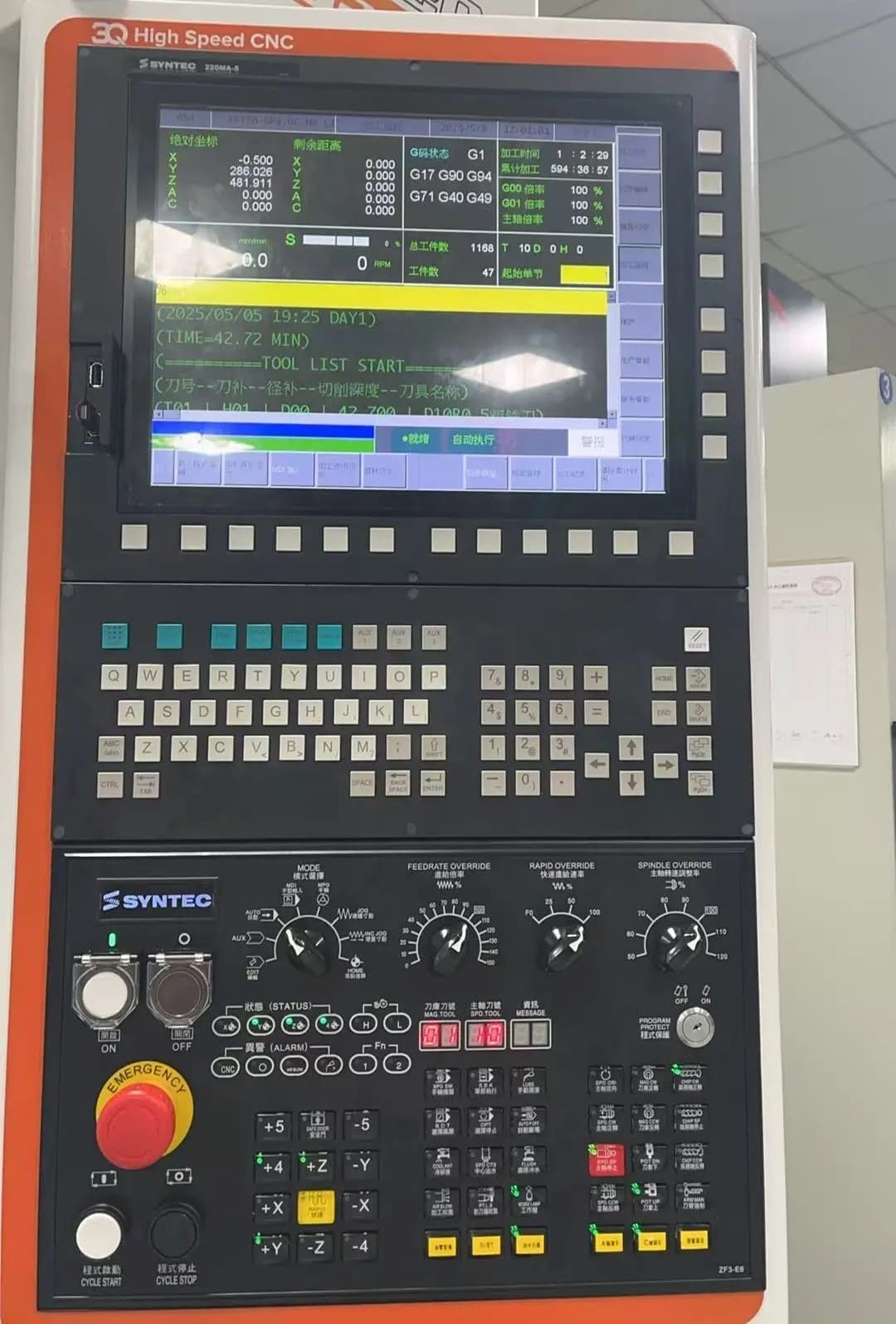

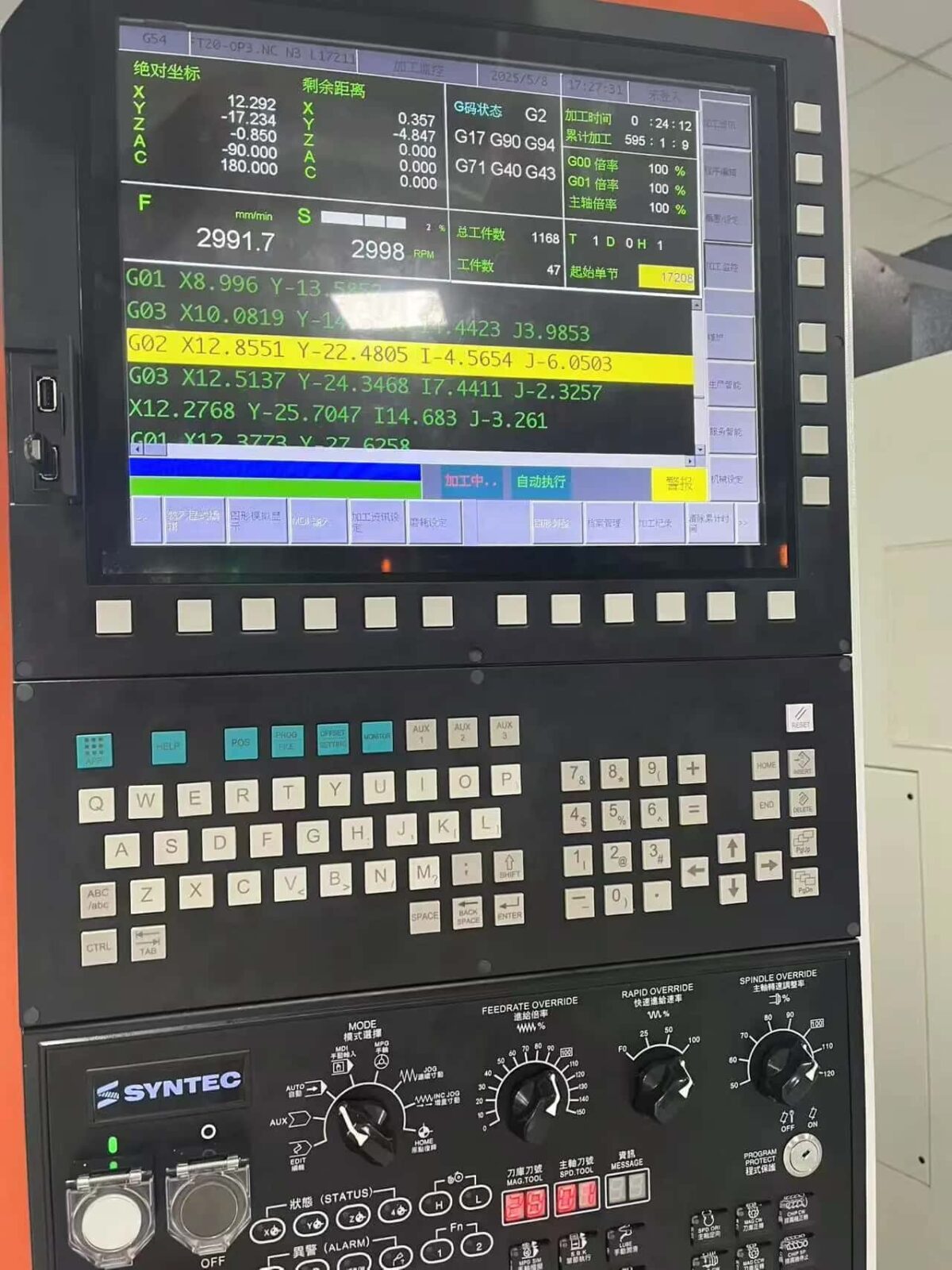

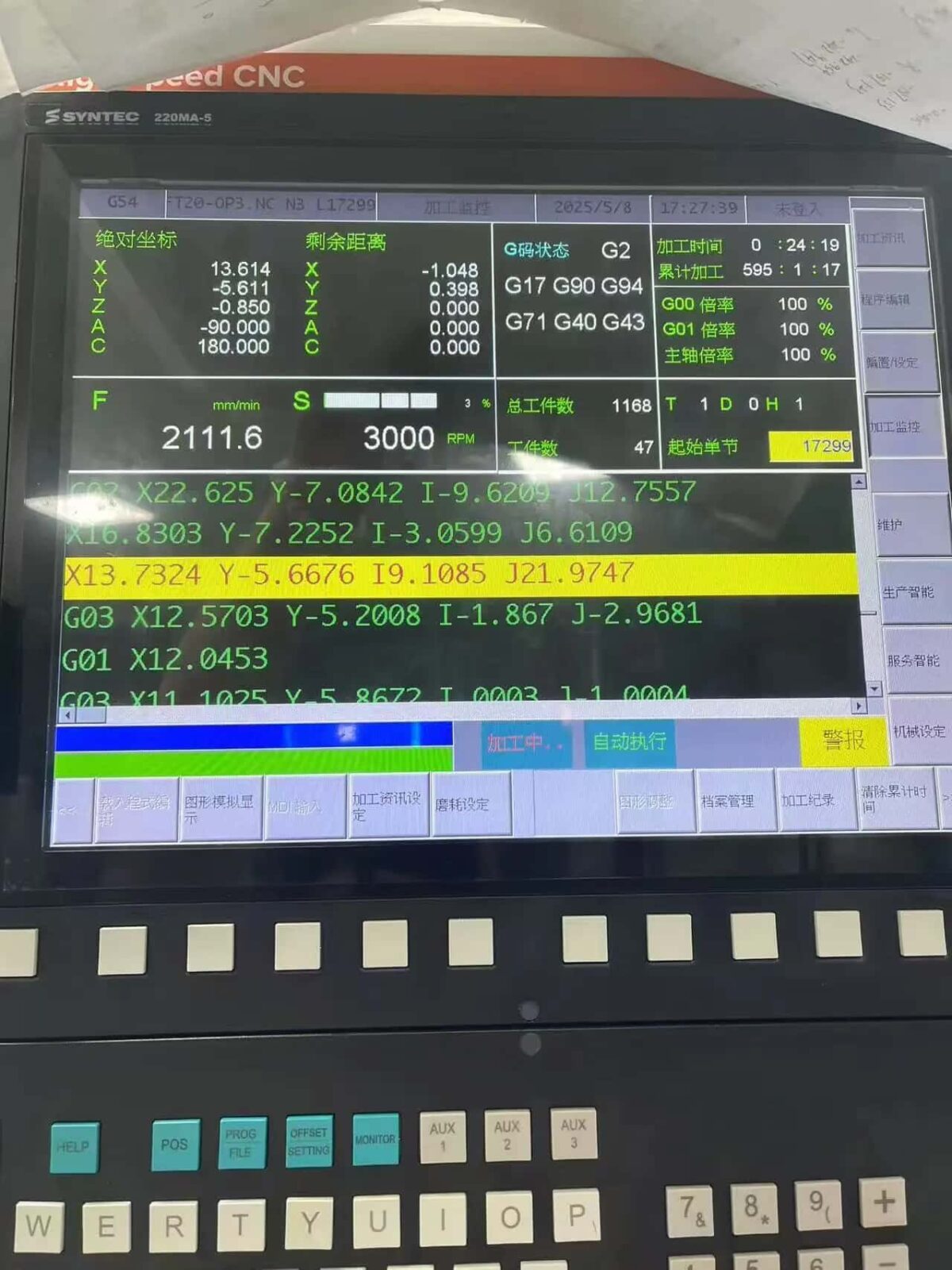

Compatible Models: SYNTEC-11MA SYNTEC-21MA-E SYNTEC-220MA-5

1. Conexión de hardware

The new-generation CNC uses Ethernet communication. Ensure the LAN port IP of the gateway and the CNC’s IP are within the same subnet (Note: In special cases, routing configuration may be required if they are not on the same subnet; consult technical support for details). IP addresses are assigned as follows in this example:

|

EG8200Mini-CNC gateway |

New Generation CNC |

|

| IP Address | 192.168.0.88 | 192.168.0.21 |

2. CNC Communication Parameters

2.1. CNC Machine IP Settings

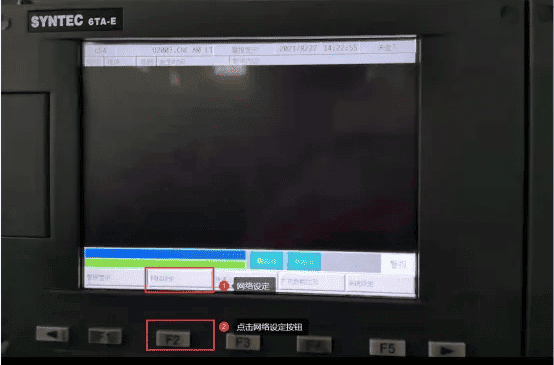

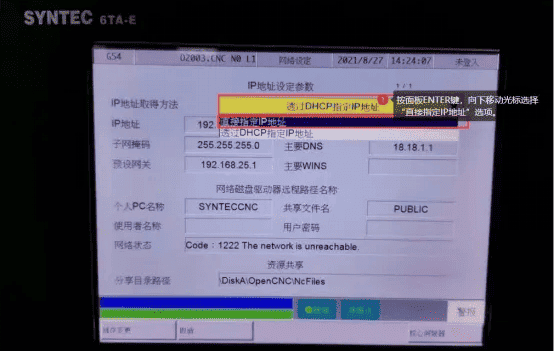

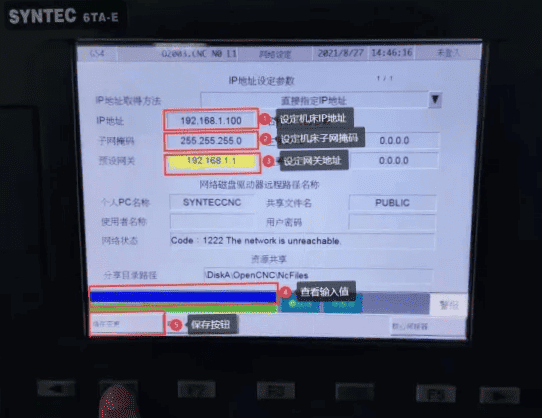

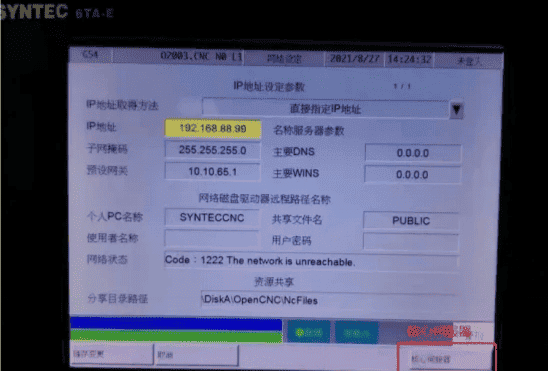

Click [Maintenance] -> [Network Settings] on the panel.

Set [IP Address Acquisition Method] to Directly Specify IP Address

2.2. Set Up Server Startup

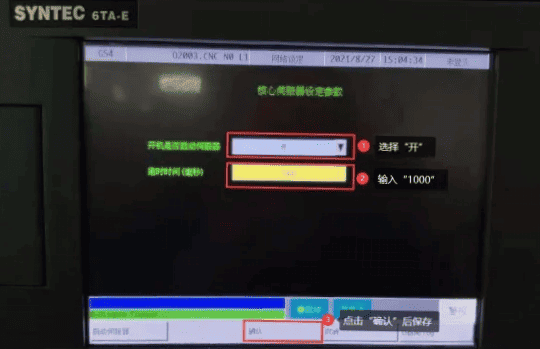

Click the Core Server icon in the bottom-right corner of the previous section’s interface.

Enable server startup on boot: On (select)

Timeout period (milliseconds): 10000 (press ENTER after input)

After configuration, restart the CNC for changes to take effect.

3. Configuración de la pasarela

3.1. CNC Connection Setup

Drag a SyntecCNC node from the left CNC panel. Double-click to open the settings page and configure as follows based on the PLC parameters:

Target IP: 192.168.0.19 (Enter the actual CNC IP address; this is the example connection IP)

Target Port: 5566 (Typically the default port)

Tiempo de espera de la conexión: 5000

Heartbeat Interval: 60000

Data Timeout: 500

Data Interval: 100

Cycle Interval: 100

3.2. Testing

Click Deploy and observe a data point being printed every few seconds. Verify the received data points to confirm successful communication!

For the data point reference table, please refer to:

Esta es una tarjeta de contenido de Yueque. Haga clic en el enlace para ver: https://iotrouter.yuque.com/zn3vdn/eg8000/rcieiq5xxxb6shkw