In this tutorial, we will focus on HAAS CNC Integration with CNC gateway. We hope this proves helpful.

In the previous lessons, we covered :

How the EG8200 Mini CNC Gateway interfaces with Siemens CNC systems

How to Integrate the CNC Gateway with Mitsubishi CNC

How to Integrate the CNC Gateway with New Generation CNC

This lesson will provide a detailed explanation for Haas CNC systems. HAAS CNC employs two communication modes: Ethernet and serial port. Below, we will address CNC gateway integration for both modes.

1.Haas CNC (Ethernet) – CNC Gateway Integration

1. Connessione hardware

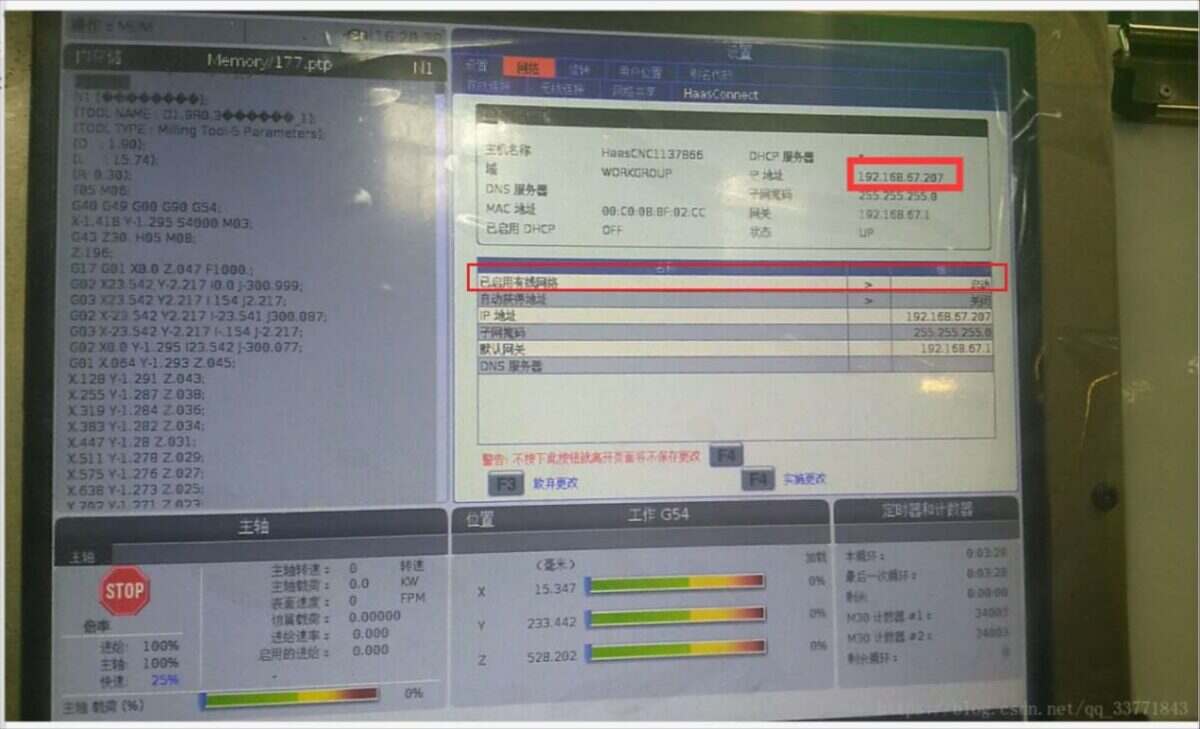

The Haas CNC communicates via Ethernet. Ensure the LAN port IP of the gateway and the Haas CNC DE IP are on the same subnet (Note: In special cases, they may be on different subnets, requiring routing configuration—consult technical support for details). IP addresses are assigned as follows in this example:

|

EG8200Mini-CNC gateway |

Haas CNC (Ethernet) |

|

| IP Address | 192.168.88.1 | 192.168.88.34 |

2. Machine Tool Setup

2.1. Locate or Configure IP in the Haas System

Locate the interface shown below and ensure the wired network status is enabled at startup:

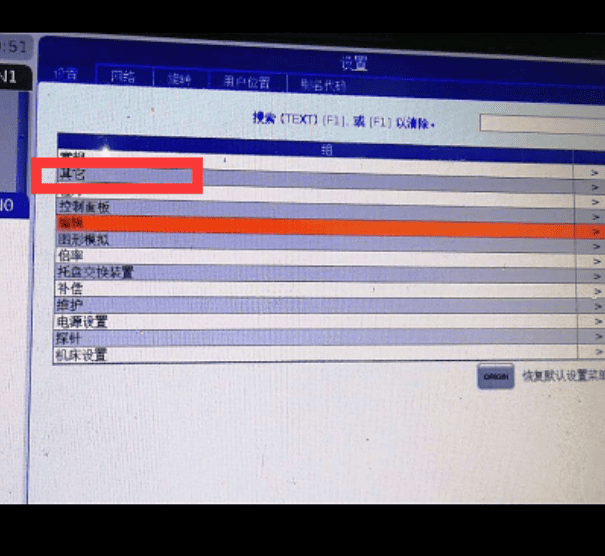

2.2. Setting the Port Number

Switch to the Settings interface (to the left of the Network Options button), select the Other tab, and enter the corresponding interface:

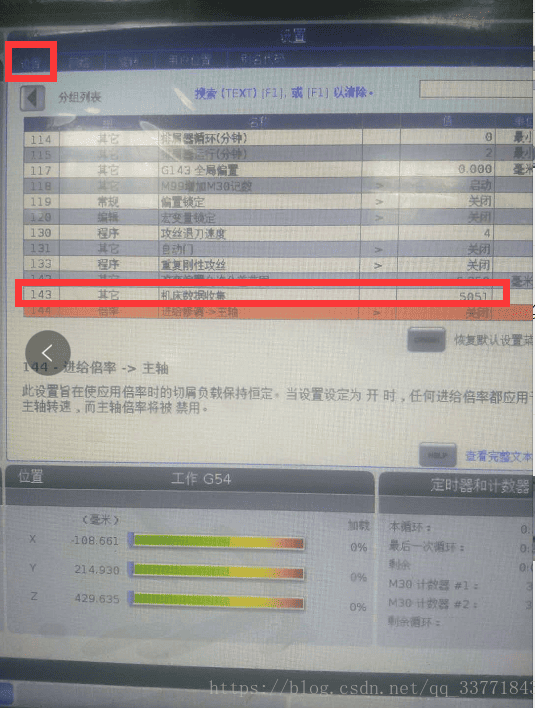

Configure the 143 parameter and set the port number:

Machine tool side setup complete. Restart the CNC.

3. Configurazione del gateway

3.1. CNC Connection Settings

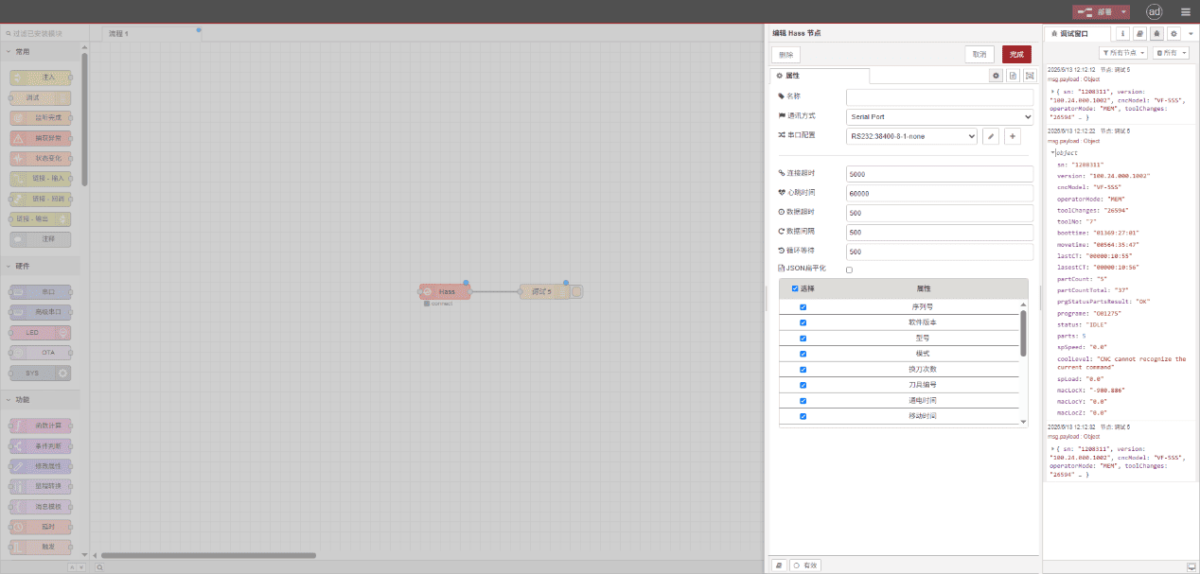

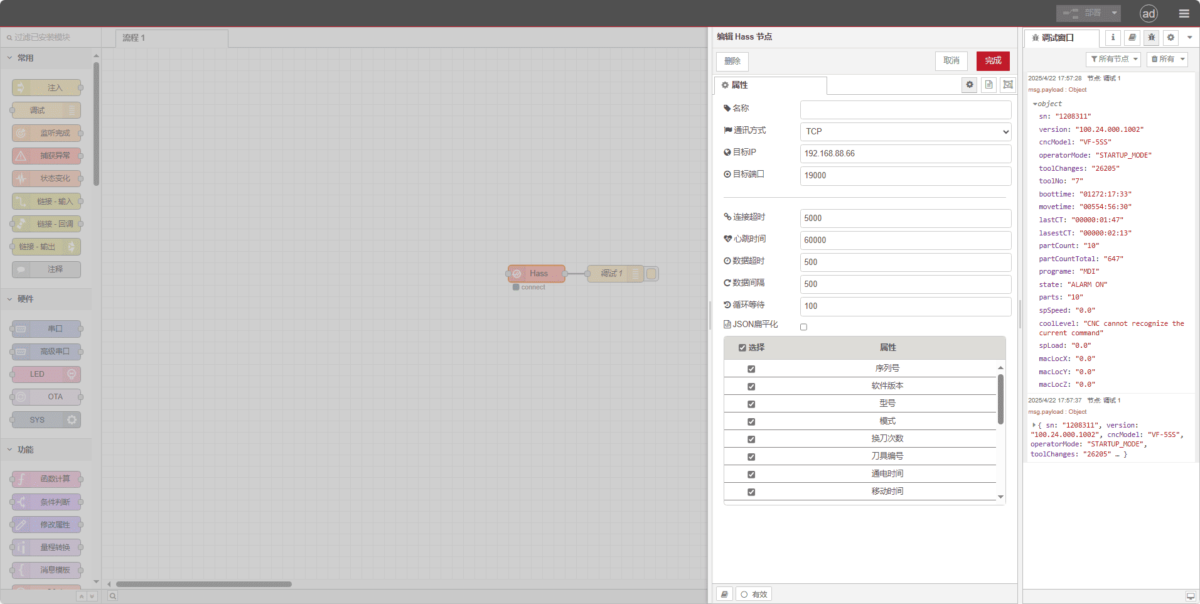

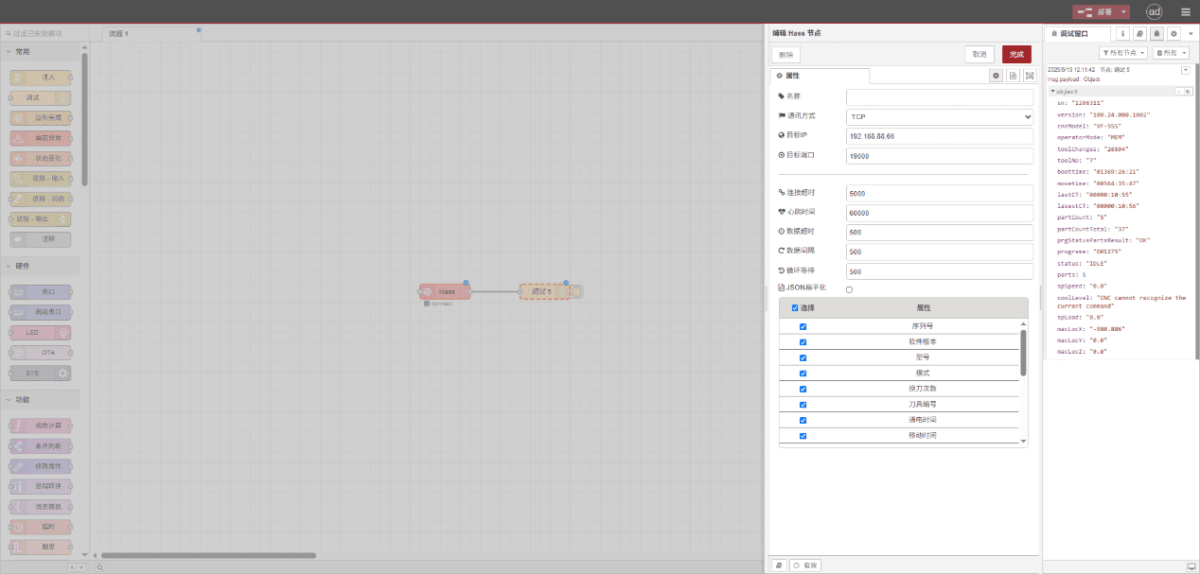

Drag a Hass node from the left panel, double-click to open the settings page, and configure as follows based on the PLC parameters:

Communication Method: TCP

Target IP: 192.168.88.66 (Replace with your machine tool’s IP)

Porto: 19000 (Enter the port configured on the machine tool)

Timeout della connessione: 5000

Heartbeat Interval: 60000

Data Timeout: 500

Data Interval: 500

Cycle Wait: 100

3.2. Testing

Click Deploy and observe a data point being printed every few seconds. Verify the received data points to confirm successful communication!

For the data point reference table, please refer to:

This is a Yueque content card. Click the link to view: https://iotrouter.yuque.com/zn3vdn/eg8000/inggeg9b79itoggq

2.Haas CNC (Serial Port) – CNC Gateway Integration

Compatible CNC: VS500

1. Connessione hardware

The Haas CNC utilizes serial communication. In this example, the CNC communication port is a DB-25 pin RS-232 interface. The TXD/RXD/GND pins must be routed out and connected to the gateway’s RS232 interface. Connect TXD to the gateway’s RX, RXD to the gateway’s TX, and GND to the gateway’s GND.

DB25 (25-pin) RS-232 Standard Pinout

| Pin Number | Nome | Direction | Descrizione |

|---|---|---|---|

| 1 | PGND | – | Protective Ground (Chassis Ground) |

| 2 | TXD | Output | Transmit Data (DTE → DCE) |

| 3 | RXD | Input | Receive Data (DCE → DTE) |

| 4 | RTS | Output | Request To Send (DTE → DCE) |

| 5 | CTS | Input | Clear To Send (DCE → DTE) |

| 6 | DSR | Input | Data Set Ready (DCE → DTE) |

| 7 | GND | – | Signal Ground (Common Return) |

| 8 | DCD | Input | Data Carrier Detect (DCE → DTE) |

| 20 | DTR | Output | Data Terminal Ready (DTE → DCE) |

| 22 | RI | Input | Ring Indicator (DCE → DTE) |

2. Machine Tool Settings

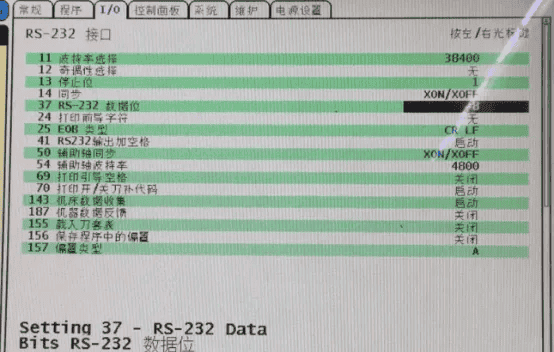

2.1. Serial Port Parameter Configuration

Click the Settings button, select I/O, and modify system parameters.

3. Gateway Settings

3.1. CNC Connection Settings

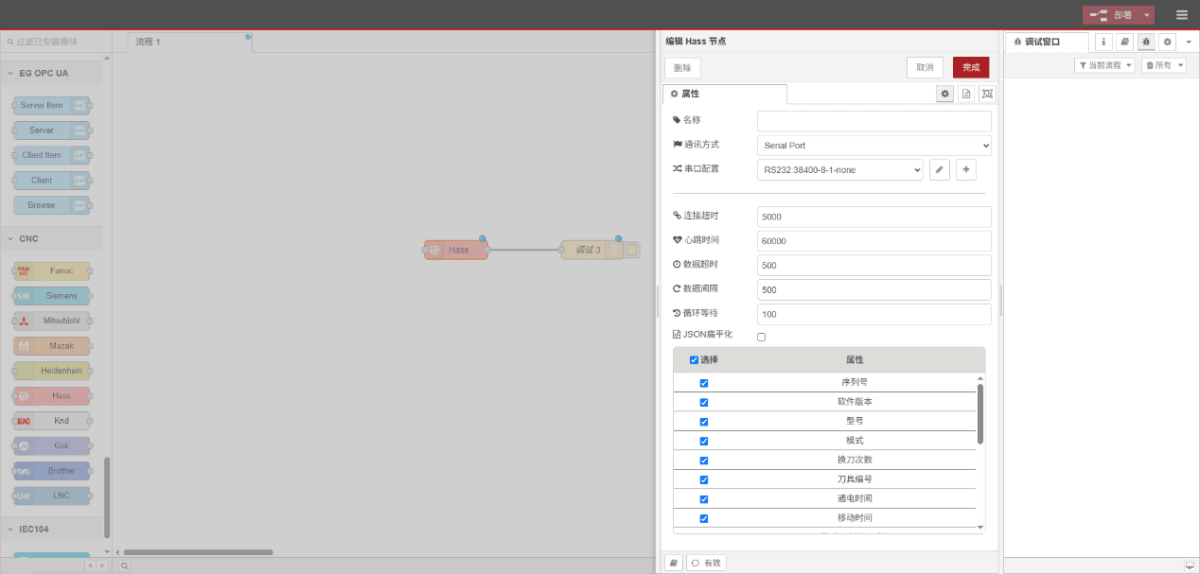

Drag a Hass node from the left panel, double-click to open the settings page, and configure as follows based on the PLC parameters:

Communication Method: Porta seriale

Serial Port: RS232

Baud Rate: 38400

Data Bits: 8

Stop Bits: 1

Parity: None

Timeout della connessione: 5000

Heartbeat Interval: 60000

Data Timeout: 500

Data Interval: 500

Cycle Wait: 100

3.2. Testing

Click Deploy and observe a data point being printed every few seconds. Verify the received data points to confirm successful communication!

For the data point reference table, please refer to:

This is a Yueque content card. Click the link to view: https://iotrouter.yuque.com/zn3vdn/eg8000/inggeg9b79itoggq