Monitoraggio remoto per macchine CNC

Contesto

High-end CNC machine tools are the "mother machines" of the manufacturing industry, with high value. For machine tool manufacturers (OEM), the traditional after-sales model is passive and costly. When a customer's machine malfunctions, engineers must be dispatched long distances to resolve the issue on-site, resulting in high travel costs, slow response times, and low customer satisfaction.

Simultaneously, the inability to obtain machine tool operating data hinders product improvement. For machine tool users, unplanned downtime leads to significant losses, and delayed maintenance can cause loss of precision. Both parties urgently need a means to achieve transparent monitoring, predictive maintenance, and remote service for machine tools, driving the manufacturing industry towards a "service-oriented" transformation.

Requisiti del cliente

- Raccolta dati

Connecting distributed CNC machine tools deployed in various locations to a cloud platform to collect data on machine tool operating status, wear and tear of vulnerable components, and electrical control systems.

- Avviso / Allarme

When a machine tool alarm occurs, the user's equipment administrator is notified within seconds. Based on historical data, the system performs health assessments and life predictions for vulnerable components such as spindle bearings and lead screws, providing early warnings.

- Operazioni / Gestione

Enables remote viewing of machine tool status, alarm history, and program code, allowing for preliminary remote diagnostics. Supports remote distribution of machining programs and PLC programs.

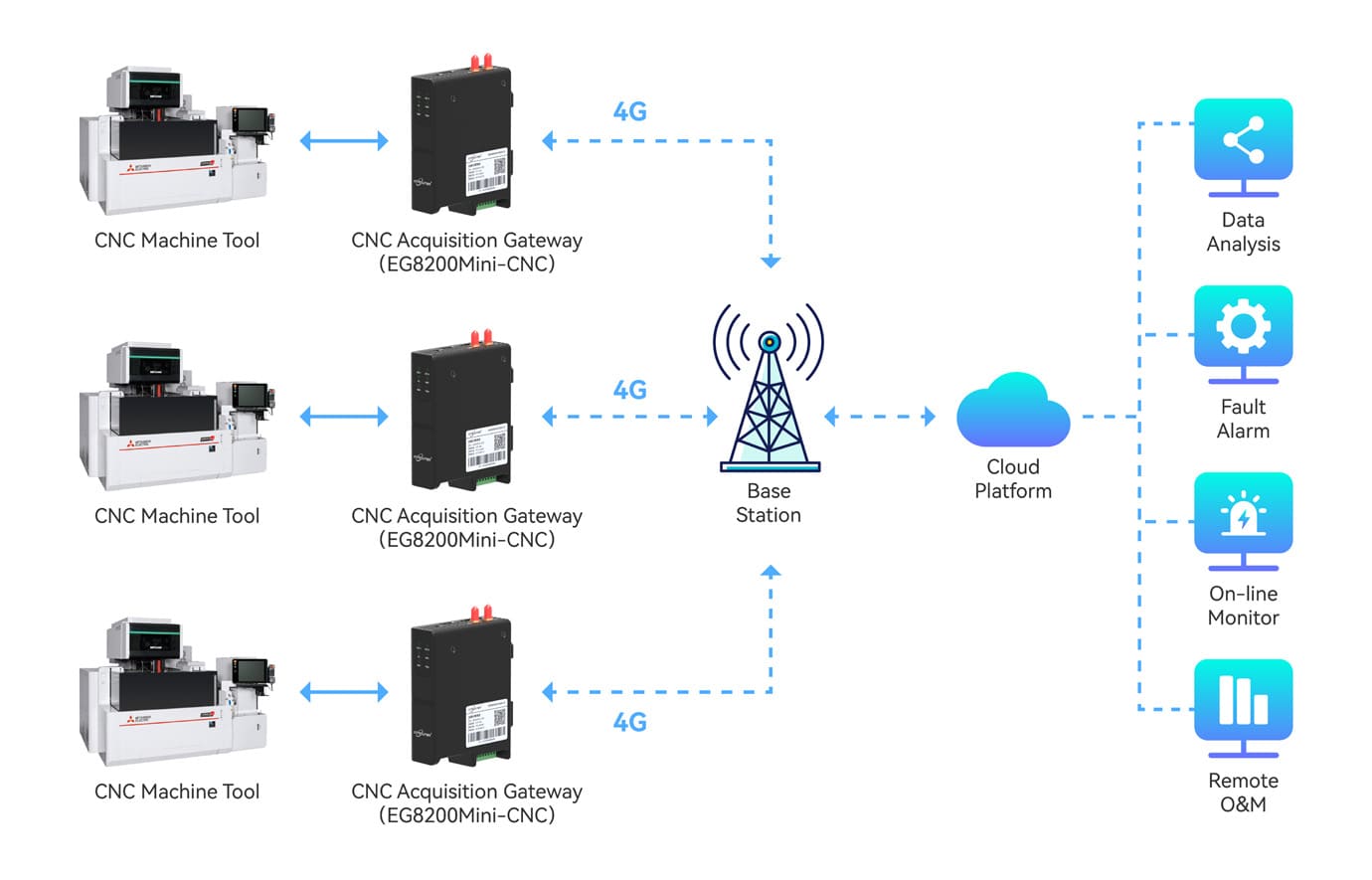

Soluzione tecnica

The system uses the EG8200Mini-CNC industrial gateway provided by IOTRouter to collect CNC machine tool data in real time and perform calculations. The data is then encrypted and transmitted to the cloud platform via 4G or the factory network.

The cloud platform utilizes intelligent algorithms for in-depth analysis, including fault prediction, energy efficiency optimization, and process parameter optimization suggestions.

EG8200Mini-CNC

The EG8200Mini-CNC is a CNC data acquisition gateway designed specifically for CNC equipment, possessing powerful edge computing, data acquisition, and remote monitoring capabilities.

It supports 2*RS485/1*RS232 hardware interfaces and multiple network options including 4G/WAN/LAN/Wi-Fi. It supports various protocols such as Modbus TCP/RTU/MQTT/HTTP/TCP/UDP/HJ212, and is compatible with CNC equipment from multiple brands including Siemens, Mitsubishi MELSEC, Mazak, Heidenhain, and Haas.

The EG8200Mini-CNC incorporates Node-RED visual programming software, enabling efficient data acquisition, data monitoring, data filtering, data security protection, data reporting, and logic processing.

It features a fully industrial design and can operate stably in temperatures ranging from - 40℃ to 80℃. It supports EMC, Opto-couplers isolation, electrostatic discharge (ESD) protection, and surge protection, ensuring reliable and stable operation in unattended environments.

System Functionality

1. Monitoring Dashboard

OEM View: Overview dashboard, health ranking, list of machine tools with warnings.

User View: Individual machine tool data charts, real-time status, alarm list, OEE reports, etc.

2. Alarm Mechanism

Supports categorized processing by alarm level; maintenance personnel can prioritize handling higher-level alarms.

3. Remote Maintenance Functions

Engineers can remotely configure, debug, diagnose, and update programs for equipment using the EG series remote management software. It can also easily create virtual LANs, enabling intranet penetration, remote PLC monitoring, debugging, and program upload/download.

Vantaggi e valore

- Vantaggi tecnici

The EG8200Mini-CNC gateway deeply analyzes the CNC protocol, ensuring professional and accurate data acquisition. Industrial-grade design, high temperature resistance, and anti-interference capabilities guarantee long-term stable operation in workshop environments. Secure architecture design ensures the security of remote access.

- Valore aziendale

For Users: Enables predictive maintenance, reduces unexpected downtime, and improves productivity; optimizes processing technology, improves equipment utilization; and reduces maintenance costs.

For OEMs: Shift from passive after-sales service to proactive service, improving customer satisfaction and loyalty; improve product design based on real data; explore new business models such as predictive maintenance and leasing services.