Télégestion des grues à tour

Contexte

The construction industry is a high-risk area for safety accidents. Tower cranes are widely used in construction due to their high-efficiency vertical transportation capabilities.

However, improper operation of tower cranes can lead to numerous high-risk situations. Traditional management methods rely on the driver's self-discipline and visual supervision by safety officers, resulting in many blind spots.

Construction companies urgently need a technological means to remotely monitor the operating status of tower cranes in real time, effectively warn of dangerous operations, and reduce accident risks.

Exigences du client

- Collecte de données

Real-time acquisition of various sensor data from the tower crane is required, including output data from tower lifting sensors, width sensors, height sensors, angle sensors, etc.

- Early Warning

Equipped with real-time automatic warning capabilities, the system triggers both audible and visual alarms when approaching or exceeding rated limits, prompting immediate corrective action.

- Operations/management

All operational logs and alarm information are recorded, creating an unalterable "black box" for tracking incidents and ensuring complete traceability for safety and maintenance.

- Visual Analysis

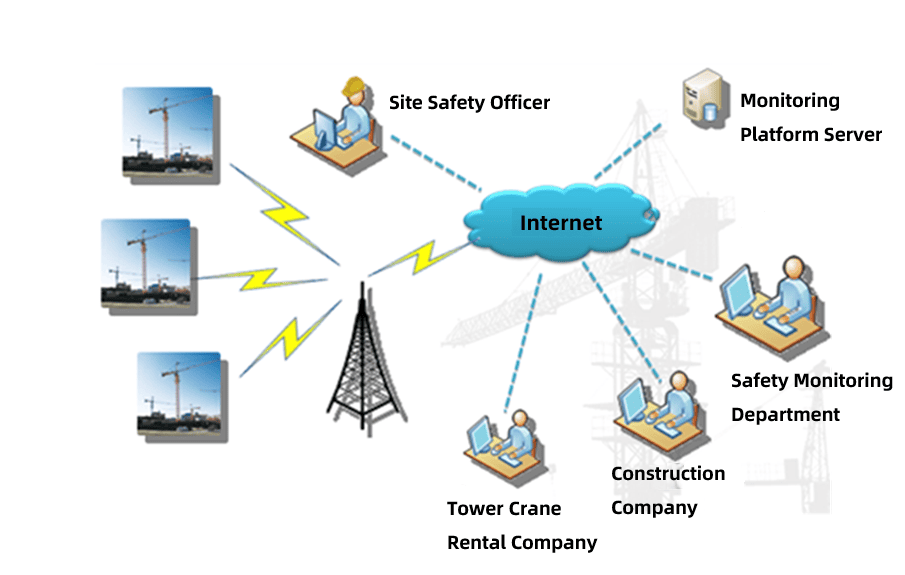

The platform offers a monitoring view of the entire tower crane fleet, displaying real-time statuses and locations, along with historical data access, alarm statistics, and operator behavior analysis for enhanced decision-making.

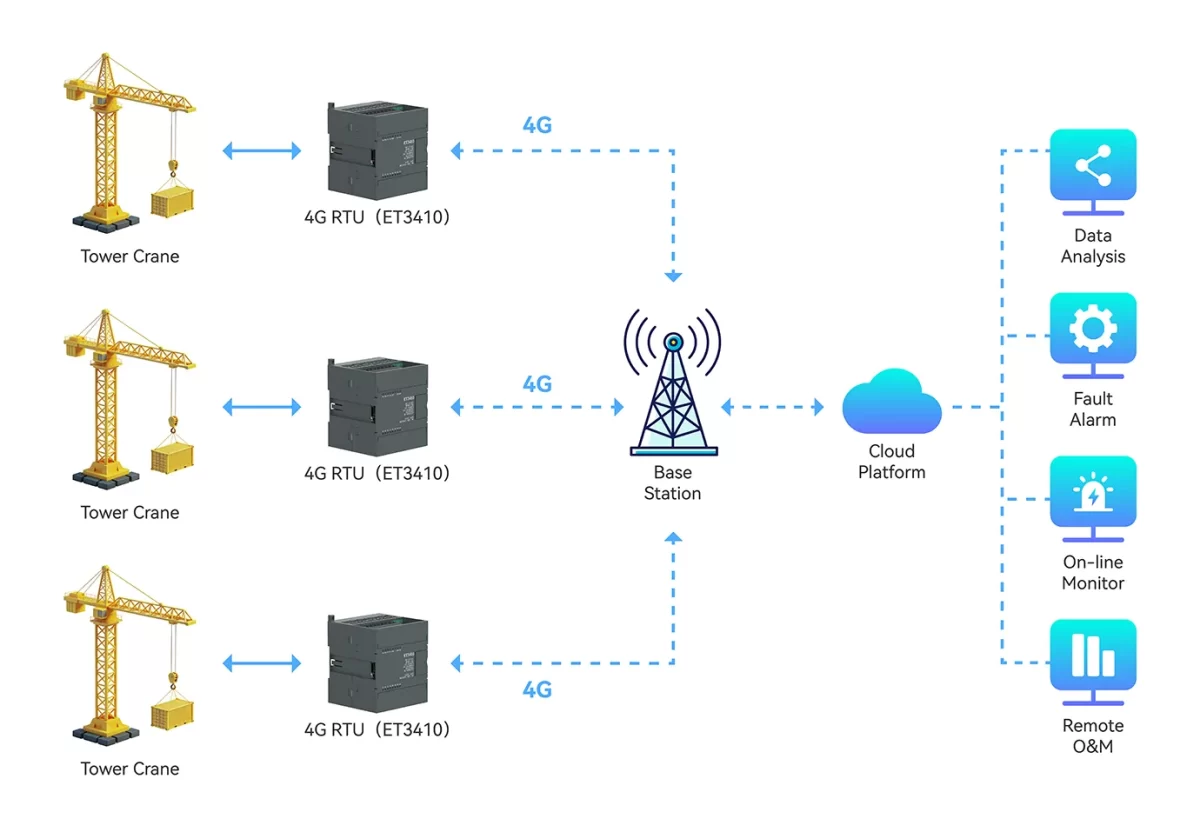

Solution technique

The system consists of three parts: tower crane monitoring devices, a wireless transmission module, and a monitoring and management center.

IOTRouter provides the ET3410 remote I/O data acquisition and control module as an intelligent terminal for the tower crane remote management solution, connecting to various sensors and uploading data to the wireless remote management platform via a 4G network.

ET3410 core features include

1. Multi-channel acquisition capability: 4*DI, 4*DO, 1*RS485

2. Seamless expansion: Its unique head-to-tail cascading design enables seamless and easy expansion of I/O interfaces.

3. Easy integration: Supports Modbus RTU/TCP and JSON protocols, eliminating complex configuration. It automatically adapts register addresses for plug-and-play functionality, simplifying the device integration process.

4. Stable Transmission: It can accommodate flexible combinations of digital and analog interfaces, easily achieving 12, 16, or 20-channel configurations while ensuring smooth network transmission.

Main System Functions

1. Acquisition des données : The host unit acquires real-time sensor signals such as amplitude, height, angle, weight, and wind speed.

2. Traitement des données : Calculates the torque value under current operating conditions in real time and compares it with preset lifting characteristic curves, executing local alarm and control logic.

3. Transmission des données : Processed key data, alarm information, and operation records are uploaded to the cloud platform in real-time via a 4G network.

4. Data Analysis: The platform stores and visualizes various types of data, providing different views and reports for different roles.

5. Multi-Level Alarms: 1. Early Warning (reaching 90% of rated value); 2. Alarm (reaching 100% of rated value, audible and visual alarm)

6. Remote Operation and Maintenance Function: Administrators can remotely view equipment status and, in special circumstances (such as severe weather), remotely issue commands to control the guide rails and grab buckets.

Avantages et valeur

- Improved Site Safety

- Digital Compliance Records