Industrial operations often face challenges in managing devices across multiple locations, T100 Networking Wizard solves these problems with easy, secure, and efficient remote networking :

-

Remote equipment sends fault alerts, but engineers can only guide on-site staff by phone.

-

Troubleshooting a PLC remotely is difficult without a public IP, and VPN setup is complicated.

-

Collecting sensor data from multiple sites incurs high costs for dedicated lines.

- ……

Challenges in Industrial Remote Access

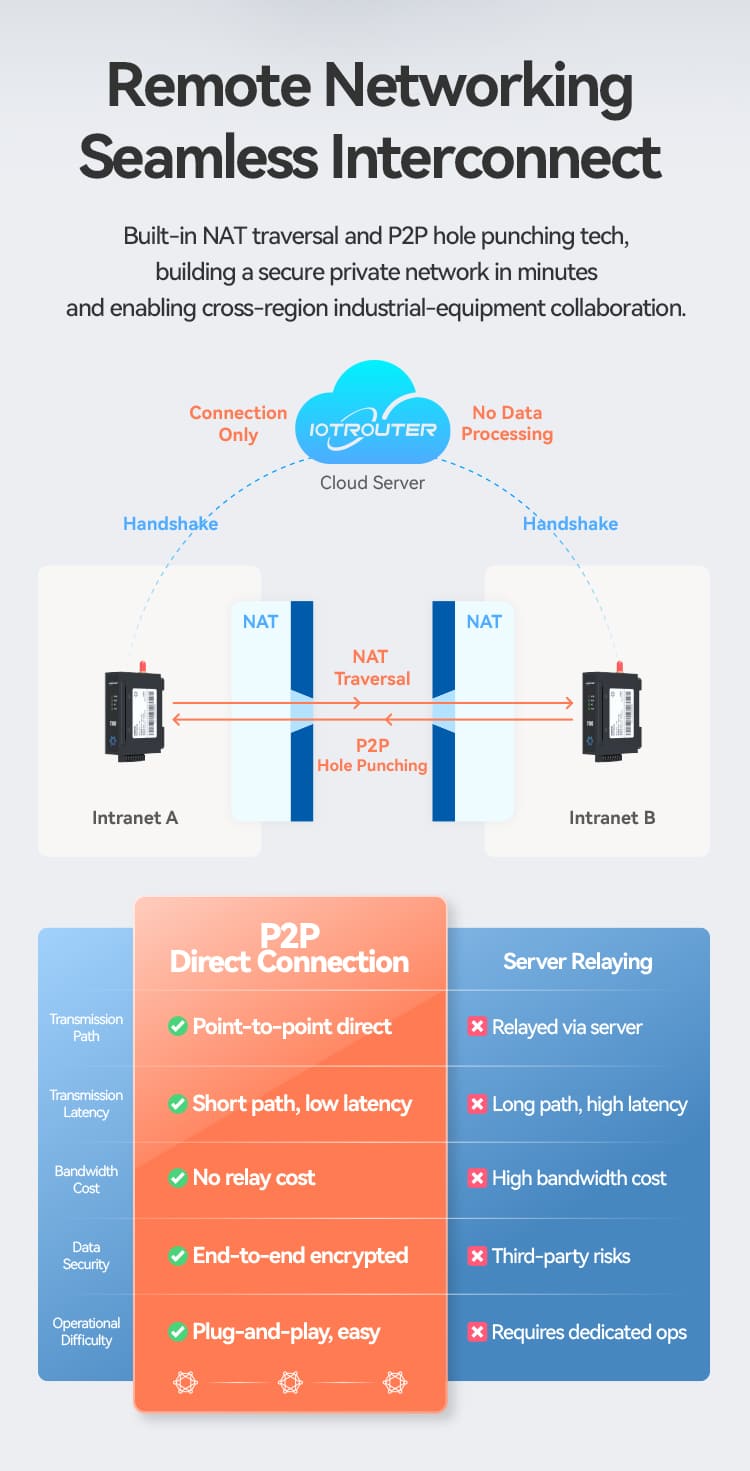

Industrial networks are often complex, distributed, and behind firewalls. Traditional remote access methods are either costly (dedicated lines) or cumbersome (VPNs, NAT traversal). T100 simplifies this by providing a direct, encrypted P2P connection, making remote access as easy as connecting devices in the same local network.

What is T100 Networking Wizard?

T100 is like giving your industrial devices an instant connection. Traditional remote networks rely on central servers to relay data, increasing latency and cost. T100 uses P2P direct connections, enabling devices to communicate directly—similar to a video call—without extra configuration.

Key Technology Features

-

Hole punching for direct connection: Devices establish encrypted communication channels after a brief handshake via the cloud.

-

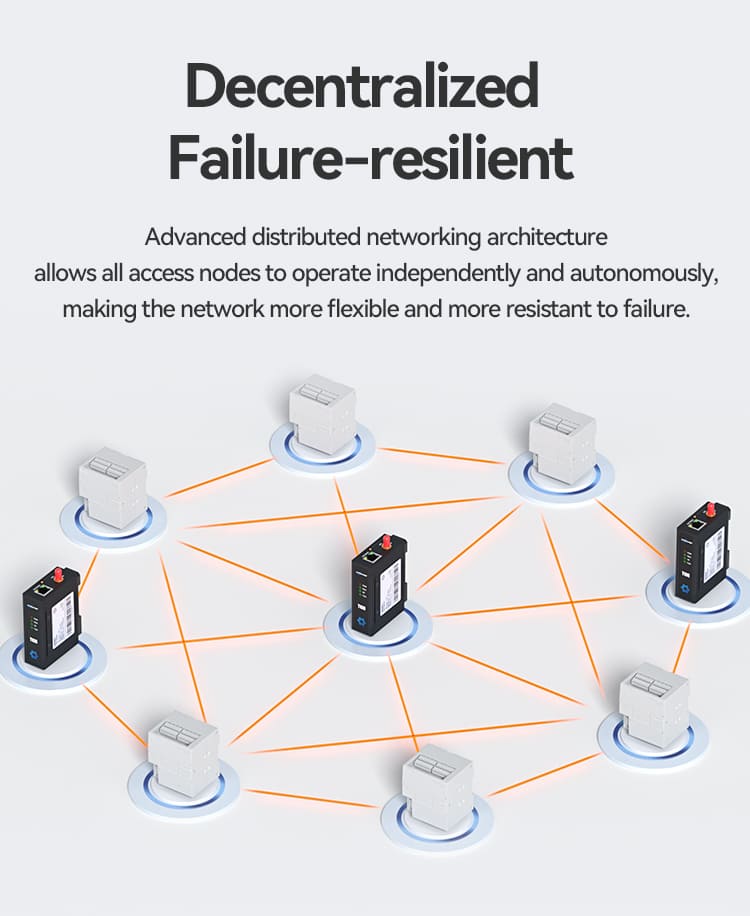

Decentralized architecture: No single point of failure; disconnected nodes do not affect others.

-

End-to-end encryption: AES-GCM ensures data is secure from start to finish, even from network providers.

-

Flexible device compatibility: Works with PLCs, cameras, networked touch screens, sensors, and more.

Think of it as building a private high-speed lane between branches, bypassing central servers.

Real-World Problems Solved by T100

Scenario 1: Remote PLC Maintenance

John, an engineer at an equipment supplier, used to fly to customer sites whenever a PLC malfunctioned. With T100 installed on-site, he can now upload and download programs directly from the office, reducing response time from 2 days to 2 minutes.

Scenario 2: Multi-Site Data Exchange

A water utility deployed monitoring devices across 10 pumping stations and connected them through a virtual LAN using T100. Data from each site flows as if all devices were in the same control room, with operational parameters displayed in real time on the central dashboard.

Scenario 3: Mobile Device Monitoring

Sensors on construction vehicles connect to the T100 network via 4G. No matter which city the vehicles travel to, the control center can access data just as if the devices were local.

Real-World Applications (Case Studies)

1. Remote Networking for Ethernet PLC (S7-200 SMART)

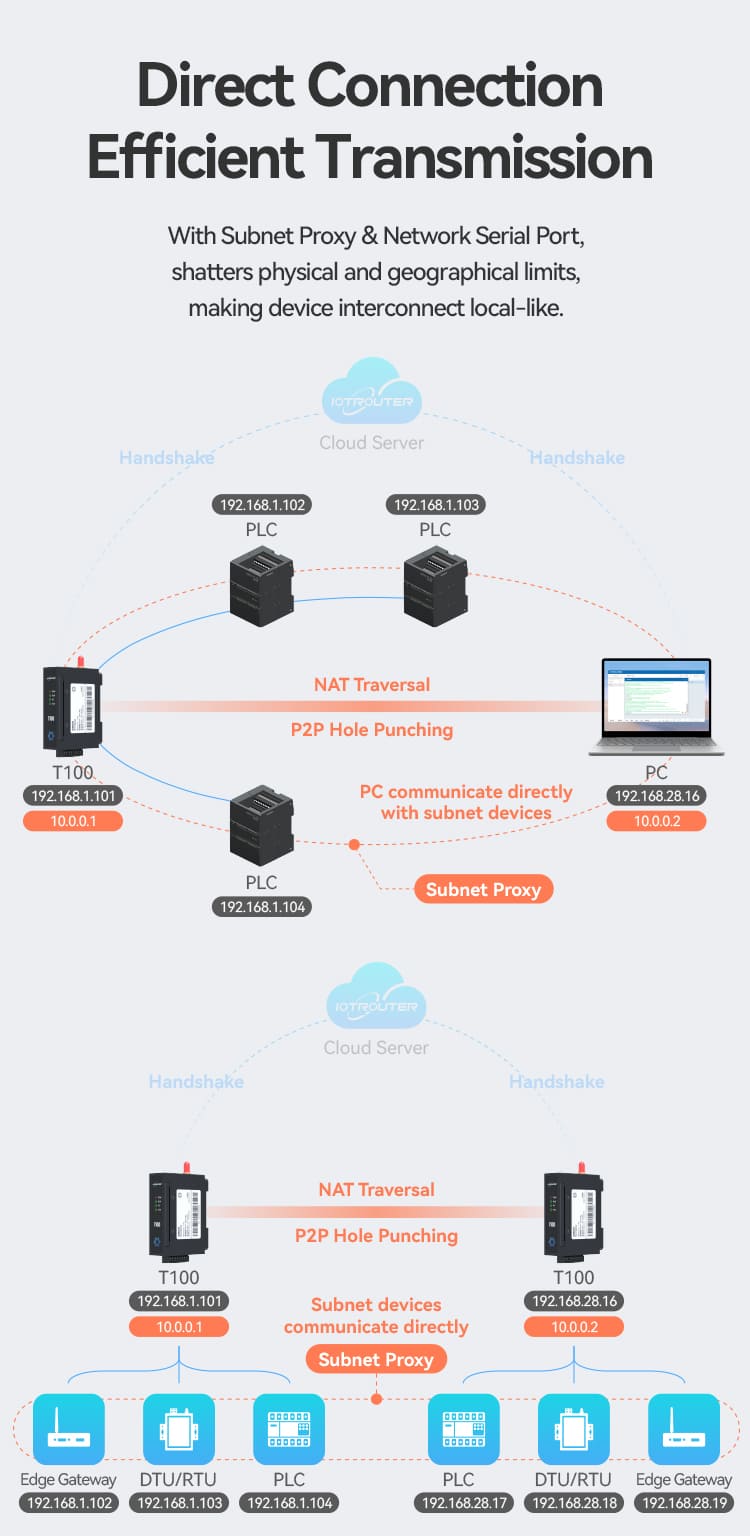

Objective: Remotely access a PLC through T100 and manage internal network devices.

Setup:

-

T100 and Siemens S7-200 SMART PLC connected to the same LAN.

-

T100 IP: 192.168.88.1, PLC IP: 192.168.88.100

-

Computer uses tun-gui software to join the virtual network.

Outcome:

-

Computer can directly communicate with PLC via P2P.

-

Remote upload/download of programs possible.

-

Solution applies to other Ethernet devices (cameras, touch screens, printers).

2. Remote Networking for Serial PLC (FX-3U)

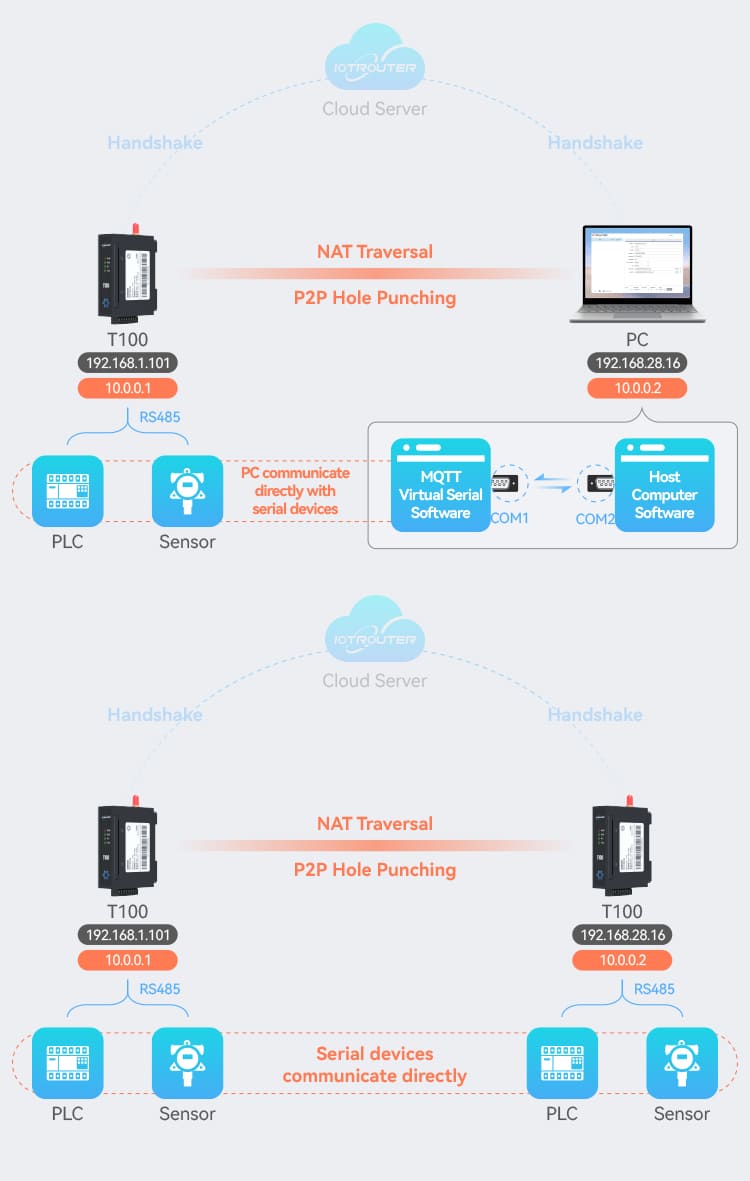

Objective: Remotely access serial devices through T100.

Setup:

-

Mitsubishi FX-3U PLC connected to T100’s serial port.

-

Virtual serial software communicates with T100’s built-in MQTT broker (no cloud relay needed).

-

Computer GUI shows successful network connection and device status.

Outcome:

-

Remote Modbus RTU communication established.

-

Works for other serial devices such as sensors, cameras, or touch screens.

3. Remote Networking Between Devices (Ethernet)

Objective: Create a virtual LAN between two remote Ethernet devices using two T100 units.

Setup:

-

Device A: S7-200 SMART PLC

-

Device B: Computer

-

T100 (A) IP: 192.168.1.101, T100 (B) IP: 192.168.28.16

-

Computer running Modbus Poll collects PLC data remotely.

Outcome:

-

P2P network successfully connects remote devices.

-

Solution works for various Ethernet devices needing cross-site communication.

4. Remote Networking Between Devices (Serial Sensors)

Objective: Remotely connect two serial devices (computer + temperature/humidity sensor) via T100.

Setup:

-

T100 (A) acts as MQTT broker, T100 (B) subscribes/publishes messages.

-

Computer reads sensor data through Modbus RTU.

-

Devices connected via RS485 and USB-to-RS485 adapter.

Outcome:

-

Full remote communication established over P2P network.

-

Compatible with other serial industrial devices (PLCs, cameras, printers, touch screens).

Vantaggi tecnici

-

Zero transit cost: P2P connections bypass third-party servers.

-

Lower latency: Data travels the shortest path, reducing delays by over 60%.

-

Easy setup: Scan a QR code, bind devices, and network them automatically.

-

Industrial durability: Wide temperature range (-20°C~85°C) and voltage input (9~36V) for harsh environments.

An automation engineer shared:

“I initially doubted that such a simple network device could handle PLC data and video monitoring without lag. In practice, it works perfectly—and there’s no need for public IPs.”

Who Can Benefit?

-

Equipment manufacturers needing remote maintenance.

-

System integrators managing multiple distributed sites.

-

Factory engineers wanting anytime, anywhere access to production line devices.

-

Projects with tight budgets but requiring reliable remote networking.

T100 Networking Wizard provides lightweight, reliable remote networking for industrial devices, making your equipment instantly reachable anywhere.