Online Monitoring System for Cigarette Factory

↑70%

↑2%

Contesto

Large domestic cigarette factories have dozens of independently operating online quality inspection devices located in dispersed locations within their packaging workshops. In the traditional model, these devices operate independently, relying on manual inspections for fault detection, resulting in delayed maintenance response and potentially leading to batch quality defects. The factory urgently needs centralized, real-time monitoring of these dispersed inspection devices, capable of promptly alerting to various hardware and software faults during production.

Requisiti del cliente

- Raccolta dati

Real-time acquisition of the operating status of cameras, control systems, and cigarette pack inspection equipment, as well as acquisition of cigarette pack integrity via DI (Digital Input) signals.

- Maintenance Management

Continuous monitoring of equipment status with an alarm and early warning system to quickly detect faults and enhance maintenance response speed. Alarms are linked with work orders to ensure smooth management from fault detection to repair completion.

- Product Quality Control

Inspection data is analyzed to identify abnormal cigarette pack defects early. This allows maintenance personnel to quickly address and repair critical equipment, ensuring effective process control of product quality.

- Analisi visiva

Production management personnel can centrally compare and analyze the operating status of testing equipment and product defects through the monitoring system, enabling efficient and centralized management of testing equipment status.

Soluzione tecnica

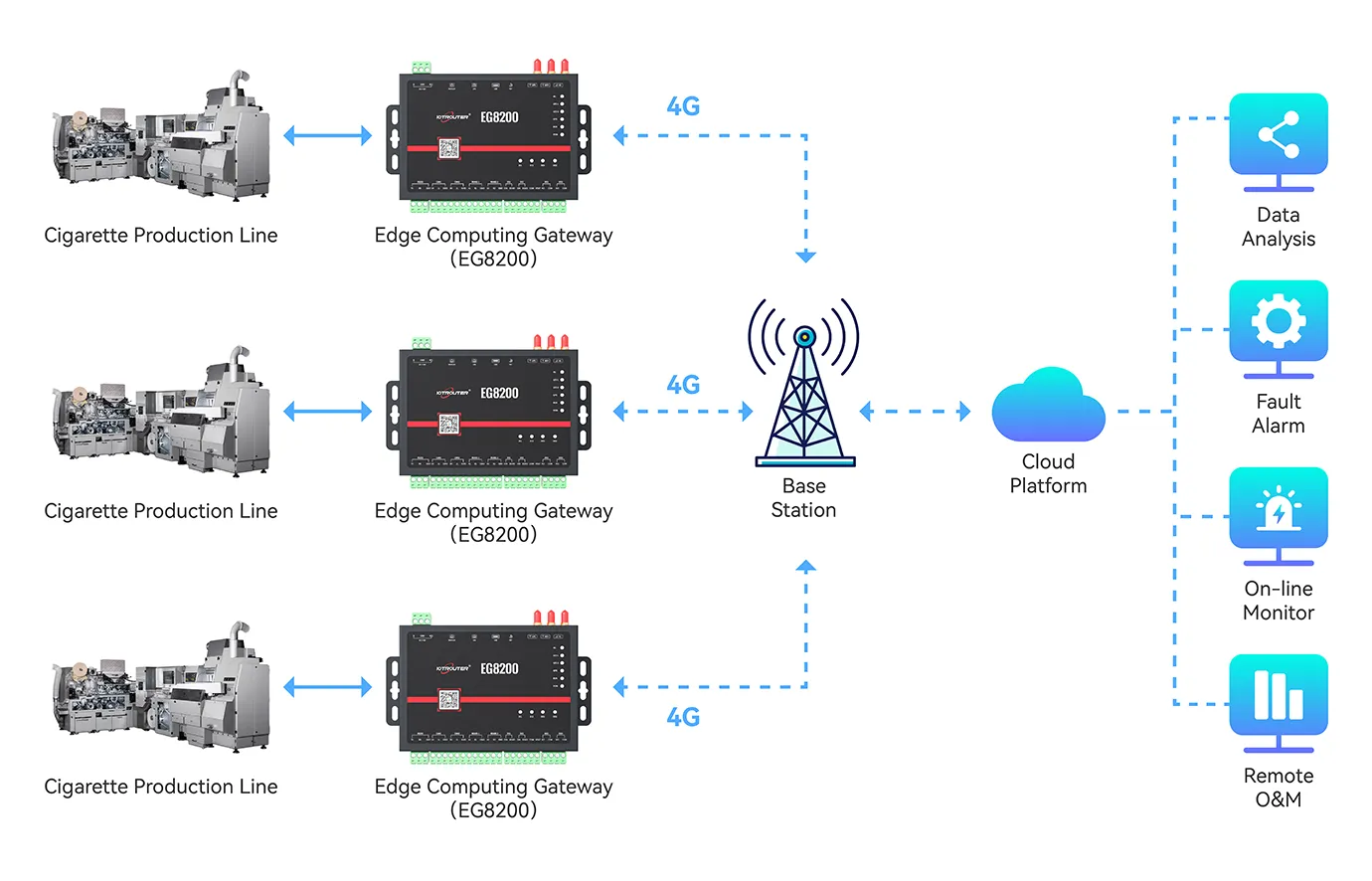

The cigarette factory's online inspection equipment monitoring system utilizes IOTRouter's EG8200 industrial edge computing gateway, employing protocols such as Modbus TCP/OPC UA to read status and alarm data from the testing equipment controller and collect high-speed switching signals through local DI points.

The processed data is transmitted to the IOTRouter IoT data platform via the workshop Ethernet using the MQTT protocol. The data platform integrates, stores, and analyzes massive amounts of data, using big data models to analyze the correlation between defect occurrence and equipment status and process parameters, providing decision support for quality improvement.

EG8200 Industrial Gateway

EG8200 is an industrial-grade edge computing gateway designed specifically for smart factories and industrial automation. It offers multiple network interfaces (4G/LAN/WAN) and a rich set of physical interfaces (2 RS485/1 RS232/2 CAN/2 DO/2 DI/1 USB2.0), easily connecting to various PLCs and field devices.

The EG8200 supports numerous protocols. It supports hundreds of PLC protocols from Siemens, Mitsubishi, Omron, LS Electric, Rockwell, Beckhoff, Inovance, Keyence, Panasonic, Delta, Xinjet, Megmeet, Yaskawa, Yung-Hung, Fengwei, Fuji Electric, and many more. It supports various industrial and sectoral protocols, such as EtherNet/IP, Modbus, OPC UA, MQTT, HTTP, TCP, IEC104, DLT645, CJ188, HJ212, SL651, etc.

EG8200 built-in Node-RED drag-and-drop programming software. Through Node-RED, users can quickly develop drag-and-drop intelligent applications, easily completing multi-protocol integration and complex automation tasks.

Core Advantages

1. Fast and efficient PLC data acquisition

2. Local processing, reducing reliance on the cloud

3. Seamless integration across multiple protocols and devices

4. Easy drag-and-drop application development

5. Industrial temperature range: -40℃ ~ 85℃, adaptable to various harsh environments

6. CE, FCC, and RoHS certifications ensure reliability

Vantaggi e valore

- Vantaggi tecnici

The high-performance processing capability of the EG8200 gateway ensures the accuracy of device status and high-speed DI signal acquisition. Extensive compatibility with industrial protocols ensures seamless integration with testing equipment from various brands. Edge computing alleviates platform load and guarantees real-time alarms.

- Valore aziendale

Enables transparent and refined management of the quality inspection process. Significantly improves the timeliness of equipment failure detection and repair response speed, reducing quality risks caused by equipment failure.