This is the context in which the EP100 Programmable DTU/RTU was born: In traditional industrial sites, “connecting a device” is often misunderstood as simply “plug in a cable, drill a hole, and that’s it.” But the real complexity lies in what comes afterward: multiple devices from different vendors with incompatible protocols, data that can’t be transmitted or decoded, heavy cloud-side processing, and frequent disconnections when the environment interferes. Increasingly, engineering projects are looking for endpoints that are lightweight—but smart.

Multi-Protocol Compatibility with EP100 Programmable DTU/RTU

The diversity of device protocols on the field is often the first hurdle for any project. The EP100 series was designed with this in mind, natively supporting major industrial protocols such as Modbus RTU/TCP and DLT645. It can parse data locally and convert it into a standardized JSON format. This may sound unremarkable, but in real-world projects it’s extremely useful—it means that data is “tidied up” before reaching the cloud, eliminating the need for back-end teams to create custom parsers for every device.

This standardization also brings flexible network topology options. Whether it’s one-to-one point-to-point communication or multi-to-one centralized collection, the EP100 can connect via serial ports and 4G passthrough, adapting to PLCs, energy meters, or environmental monitoring devices.

Put some “brains” at the edge, not all in the cloud

Traditional sensors or acquisition terminals are often “dumb” devices—they push every piece of data straight to the cloud. The EP100 Programmable DTU/RTU acts more like a “front-end processor,” supporting local logic, data filtering, linear conversion, active polling, and conditional reporting. For example, a water pump monitoring point doesn’t need to push pressure values every second. Instead, you can set thresholds so that data is only sent when values exceed or return to normal. This reduces unnecessary traffic and eases the cloud’s processing load.

In large-scale deployments, this “edge offloading” is particularly effective. Clean data means lower latency and faster response times.

Industrial-grade survivability

The EP100 is not an office gadget—it’s designed for industrial environments. Operating temperatures range from -40°C to 85°C, with a 9–36V wide voltage input. It’s built to resist static, surges, and reverse connections, and features both hardware and software watchdogs to ensure continuous 24/7 operation, even in humid, dusty, or high-interference environments. Such stability is crucial in distribution cabinets, pump stations, greenhouses, and other locations that are difficult to service frequently.

Not just “use it”—you can “program it”

Another interesting feature of the EP100 Programmable DTU/RTU is support for microPython for secondary development. For developers, this means you can implement specific logic locally, without being restricted by the manufacturer’s fixed functions. You can perform data cleaning, status evaluation, event triggering, or even create private protocol logic with custom heartbeat and registration packets. This is highly flexible for integrators needing to quickly adapt to on-site requirements.

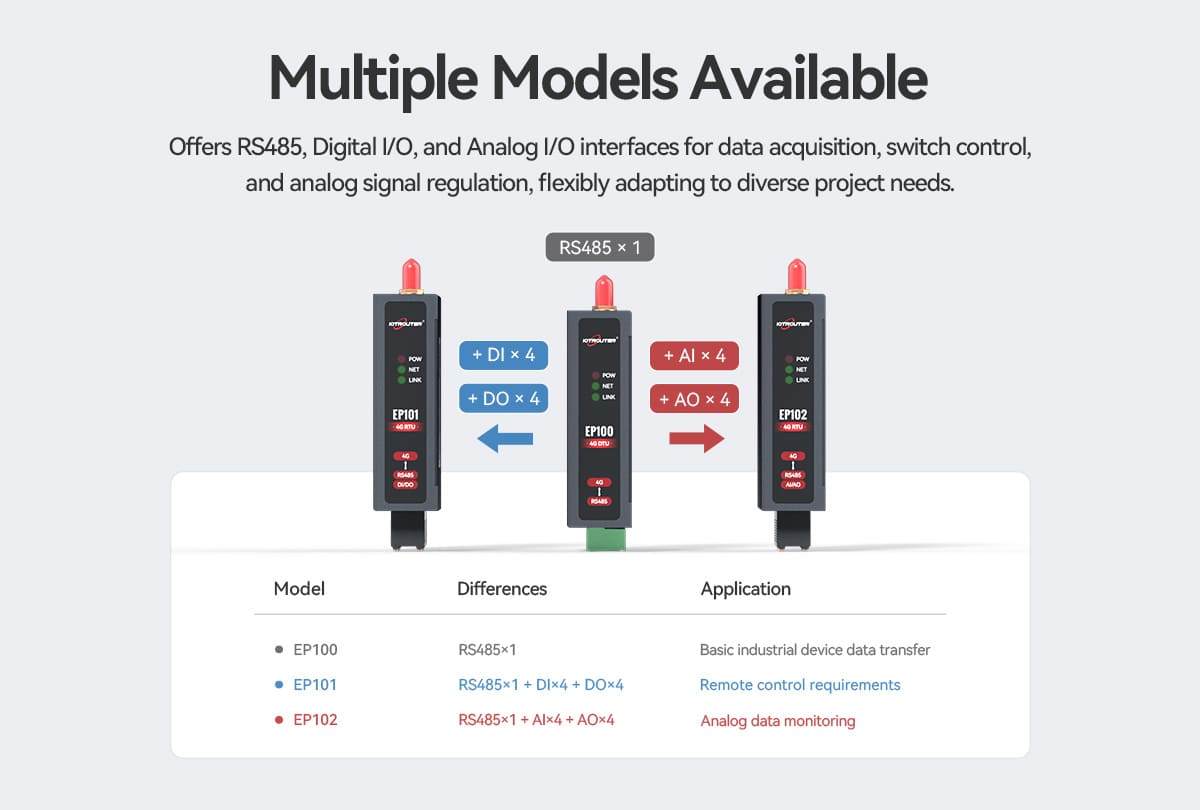

Different models for different scenarios

The EP100 Programmable DTU/RTU isn’t a “one-size-fits-all” box—it’s split into three models to suit different needs:

EP100: Basic RS485 acquisition, suitable for standard industrial data upload.

EP101: Adds DI/DO interfaces for scenarios requiring switch control, such as pump and valve coordination.

EP102: Expands AI/AO interfaces for analog acquisition and control, such as pressure, level, or flow monitoring.

This streamlined model differentiation avoids “buying features you don’t need” and helps control project costs.

Applications span multiple industries

In smart water projects, it can collect water pressure and level data and trigger pump or valve control.

In energy management projects, it can collect electricity meter readings and report load data.

In smart agriculture, it coordinates temperature and humidity collection with irrigation control.

In other words, it can be both a “data acquisition terminal” and, to some extent, an “edge controller.”

In conclusion

The EP100 Programmable DTU/RTU is not just a “fancier DTU”—it plays the role of a smarter “connection node” in industrial IoT infrastructure. It integrates protocol handling, logic evaluation, and data transmission into a single device, pragmatically lowering the barrier to connectivity and making complex, costly systems easier to deploy.

For many small to medium-sized projects, this design is more practical than stacking functions. Its true value isn’t in the number of specs on a datasheet—it’s in its ability to deliver data safely and reliably to where you need it.