In this tutorial, we will focus on how the EG8200 Mini CNC Gateway works with Mitsubishi CNC systems. We hope this proves helpful.

In the previous lesson, we covered how the EG8200 Mini CNC Gateway interfaces with Siemens CNC systems. This lesson will provide a detailed explanation for Mitsubishi CNC systems.

1. EG8200 Mini CNC Gateway

Сайт EG8200 Mini CNC Gateway is a data acquisition gateway specifically designed for CNC machine tools, featuring robust data collection and remote monitoring capabilities. This device supports multiple industrial protocols including Modbus and MQTT, is compatible with CNC machine tools from various brands, and empowers users to achieve remote management of their machine tools.

2. Siemens CNC VS. Mitsubishi CNC

Siemens CNC (Siemens SINUMERIK) originates from Germany and is the most widely used CNC system in Europe. It demonstrates significant advantages in high-end equipment applications such as five-axis machining, large gantry milling, and aerospace manufacturing.

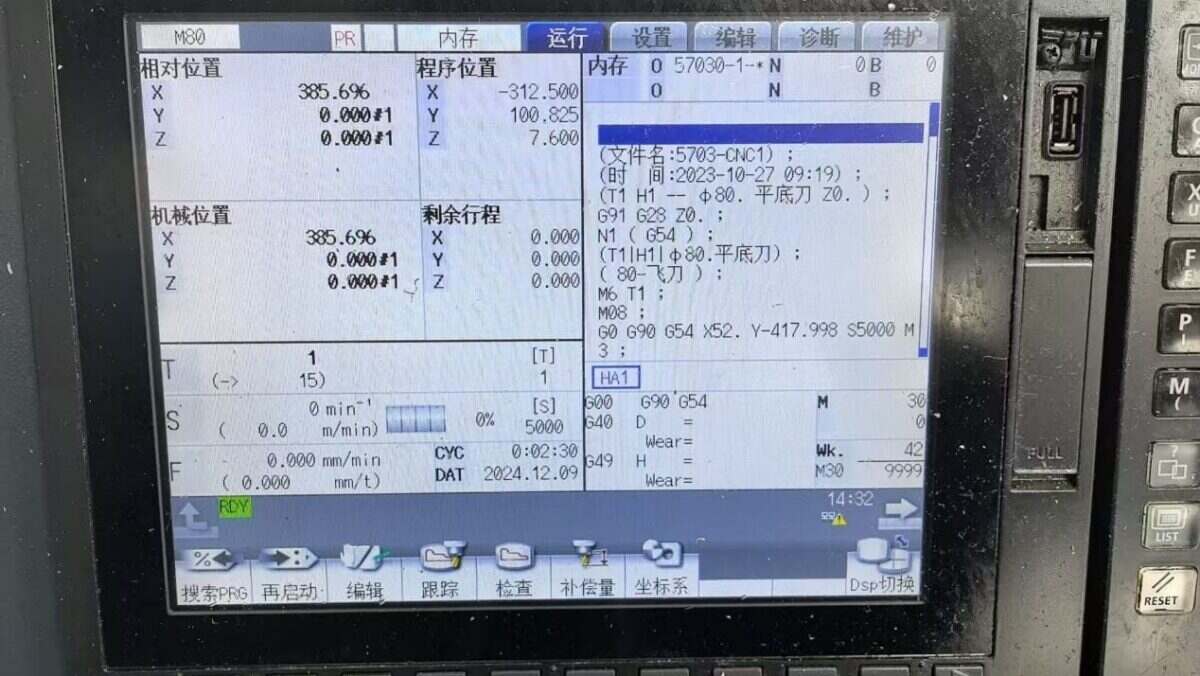

Mitsubishi CNC (Computer Numerical Control), developed by Japan’s Mitsubishi Electric, is widely used on machine tools in Japan and China. Mitsubishi CNC excels in small-segment interpolation and high-speed, high-precision machining, making it particularly suitable for mold manufacturing and precision parts processing in the 3C industry.

3. How to Interface the EG8200Mini-CNC gateway with Mitsubishi CNC

Compatible CNC Models: M800/M80/M700V/M70V/E70/C70

1. Подключение оборудования

The Mitsubishi CNC protocol utilizes Ethernet communication. Therefore, ensure the gateway’s LAN port IP and the CNC’s IP are within the same subnet (Note: In special cases, routing configuration may be required if they are not on the same subnet; consult technical support for details). IP addresses are assigned as follows in this example:

|

EG8200Mini-CNC gateway |

Mitsubishi CNC |

|

| IP Address | 172.16.21.2 | 172.16.21.102 |

2. CNC Communication Parameters

Provided by the CNC engineer:

The CNC network port parameters are:

IP: 172.16.21.102 Port: 683

3. Gateway Settings

3.1. CNC Connection Settings

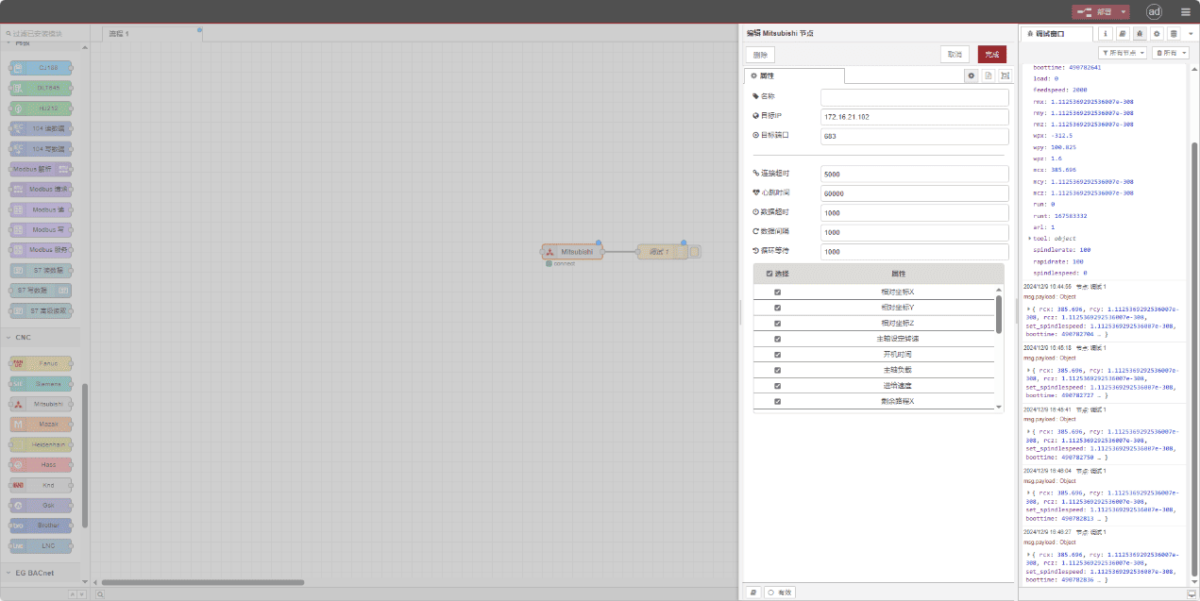

Drag a Mitsubishi node from the left CNC panel, double-click to open the settings page, and configure as follows based on the PLC parameters:

Адрес: 172.16.21.102

Порт: 683

Таймаут соединения: 5000

Heartbeat Interval: 60000

Data Timeout: 2000

Data Interval: 1000 (Read Cycle)

Cycle Wait: 1000 (Data Point Read Interval)

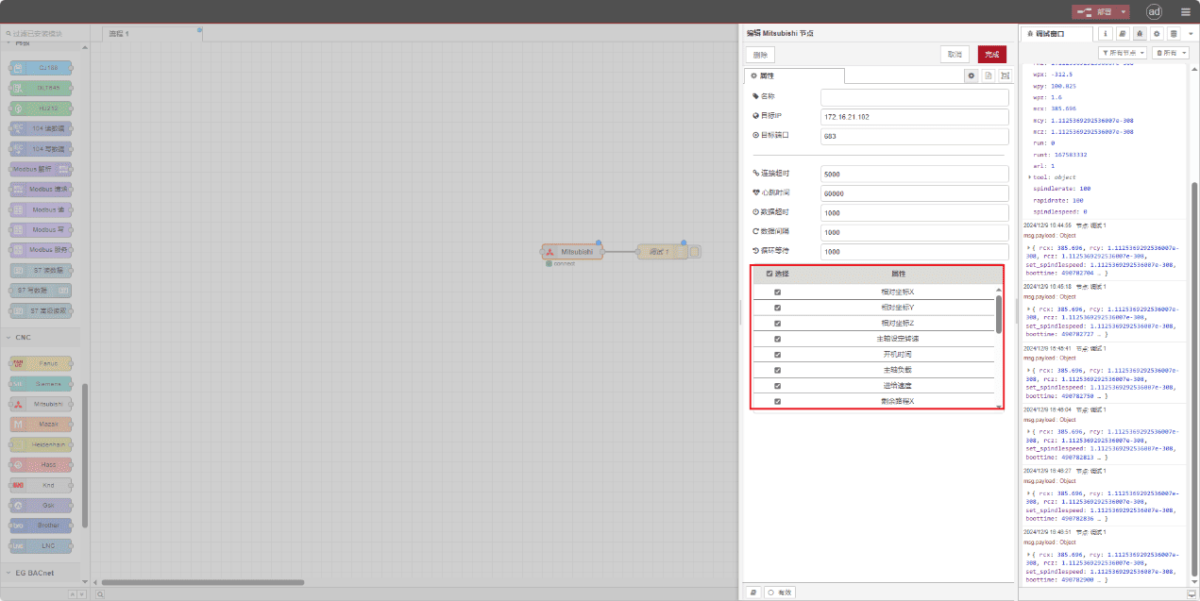

3.2. Data Point Settings

Check the required data points:

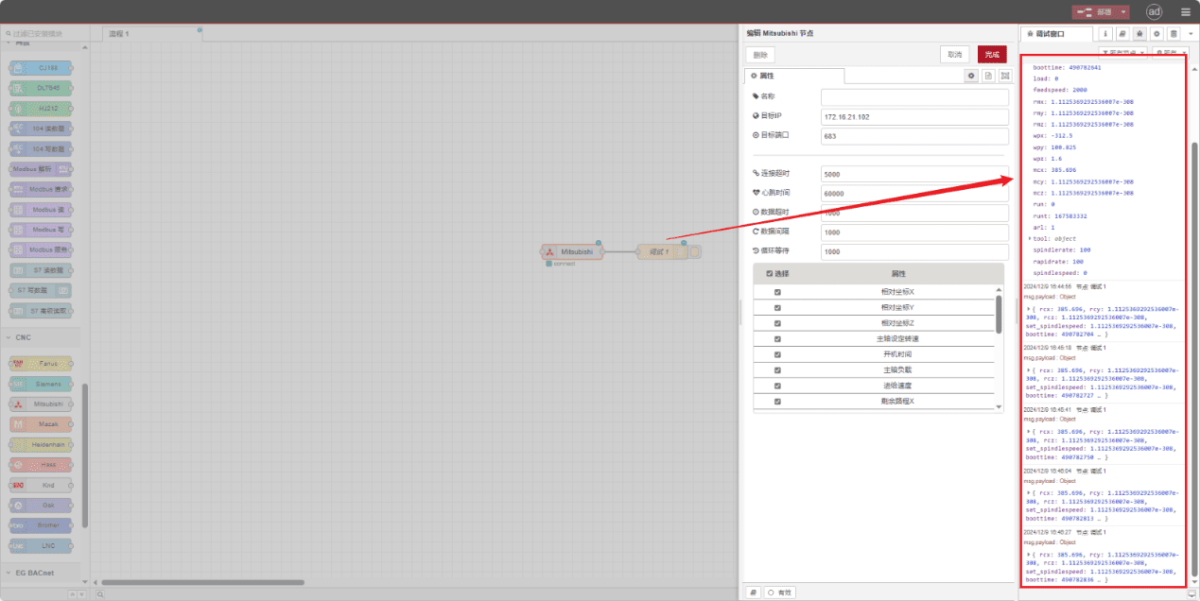

3.3. Testing

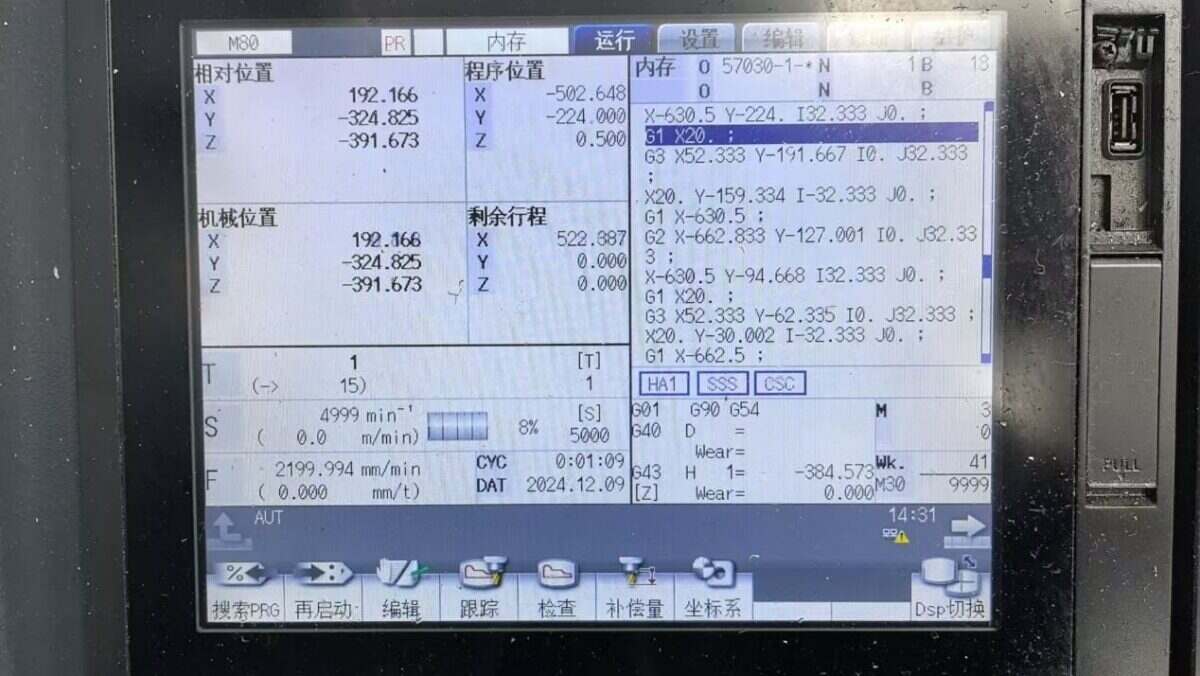

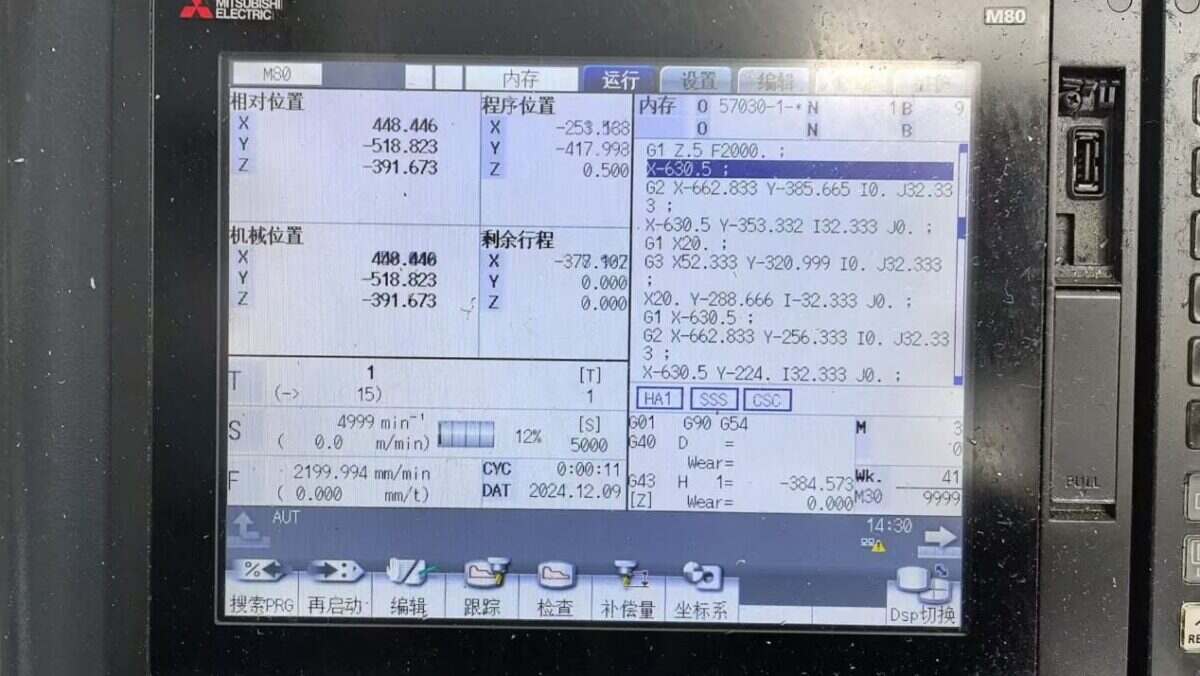

Click Deploy and observe a data point being printed every few seconds. Verify the received data points to confirm successful communication!

For the data point reference table, please refer to:

This is a Yueque content card. Click the link to view: https://iotrouter.yuque.com/zn3vdn/eg8000/ebxwp1ndwhn988w3