Torenkraan afstandsbediening

Achtergrond

De bouwsector is een gebied met een hoog risico op veiligheidsongevallen. Torenkranen worden veel gebruikt in de bouw vanwege hun zeer efficiënte verticale transportmogelijkheden.

Onjuiste bediening van torenkranen kan echter leiden tot talloze risicovolle situaties. Traditionele managementmethoden vertrouwen op zelfdiscipline van de bestuurder en visueel toezicht door veiligheidsfunctionarissen, wat resulteert in veel blinde vlekken.

Bouwbedrijven hebben dringend behoefte aan technologische middelen om de bedrijfsstatus van torenkranen in realtime op afstand te bewaken, effectief te waarschuwen voor gevaarlijke handelingen en het risico op ongelukken te verkleinen.

Eisen van de klant

- Gegevensverzameling

Real-time verwerving van verschillende sensorgegevens van de torenkraan is vereist, waaronder outputgegevens van torenhefsensoren, breedtesensoren, hoogtesensoren, hoeksensoren, enz.

- Vroegtijdige waarschuwing

Het systeem is uitgerust met realtime automatische waarschuwingsfuncties en geeft zowel akoestische als visuele alarmen af wanneer de nominale limieten worden benaderd of overschreden, zodat er onmiddellijk corrigerende maatregelen worden genomen.

- Operaties/beheer

Alle operationele logboeken en alarminformatie worden vastgelegd, waardoor een onveranderlijke "zwarte doos" ontstaat voor het traceren van incidenten en het garanderen van volledige traceerbaarheid voor veiligheid en onderhoud.

- Visuele analyse

Het platform biedt een bewakingsoverzicht van de gehele torenkraanvloot, met realtime statussen en locaties, samen met toegang tot historische gegevens, alarmstatistieken en gedragsanalyse van de operator voor verbeterde besluitvorming.

Technische oplossing

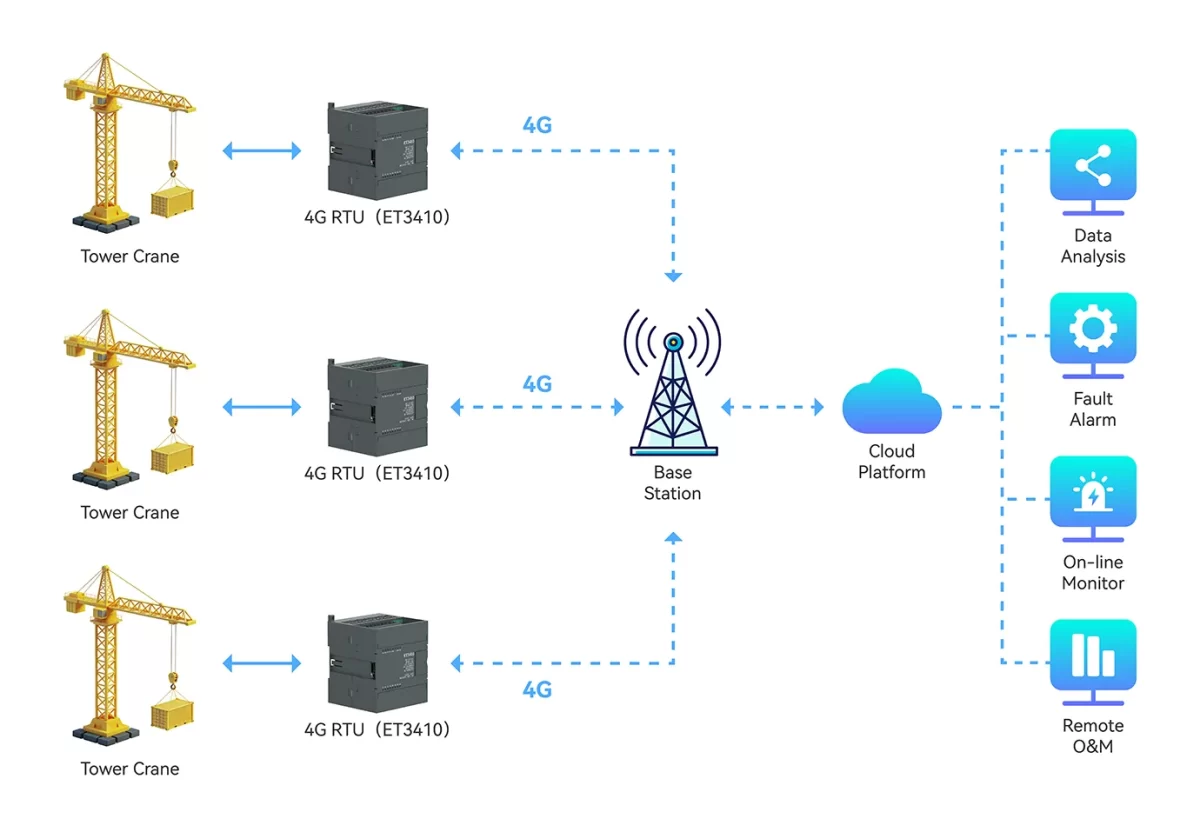

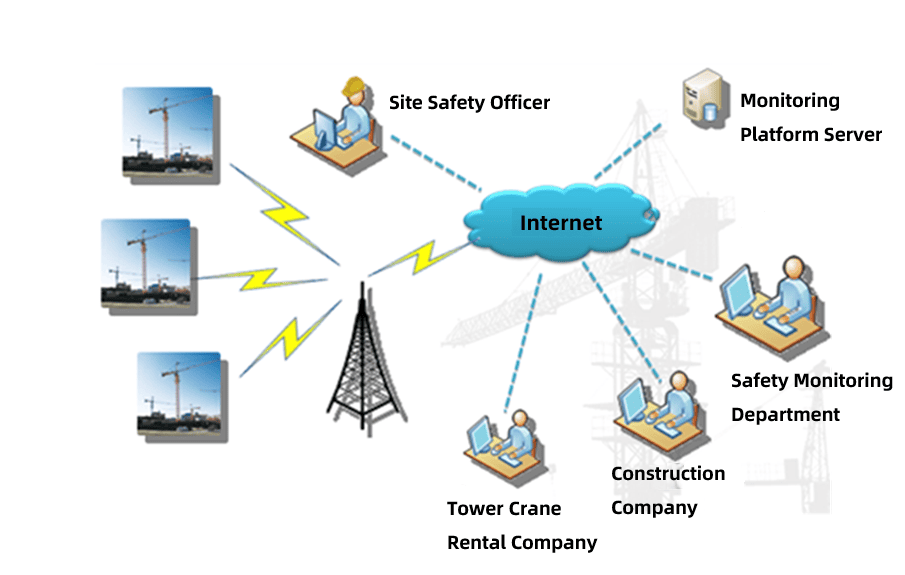

Het systeem bestaat uit drie delen: apparatuur voor het monitoren van torenkranen, een draadloze transmissiemodule en een monitoring- en beheercentrum.

IOTRouter levert de ET3410 remote I/O data-acquisitie en controlemodule als een intelligente terminal voor de oplossing voor beheer op afstand van torenkranen, die verbinding maakt met verschillende sensoren en gegevens uploadt naar het draadloze platform voor beheer op afstand via een 4G-netwerk.

De belangrijkste functies van de ET3410 zijn

1. Multikanaals acquisitievermogen: 4*DI, 4*DO, 1*RS485

2. Naadloze uitbreiding:Het unieke kop-staart cascadeontwerp maakt naadloze en eenvoudige uitbreiding van I/O-interfaces mogelijk.

3. Gemakkelijke integratie: Ondersteunt Modbus RTU/TCP en JSON protocollen, waardoor complexe configuratie overbodig is. Het past automatisch registeradressen aan voor plug-and-play functionaliteit, wat het apparaatintegratieproces vereenvoudigt.

4. Stabiele transmissie: Het kan flexibele combinaties van digitale en analoge interfaces aan, waardoor gemakkelijk 12, 16 of 20-kanaals configuraties kunnen worden bereikt en een soepele netwerktransmissie wordt gegarandeerd.

Belangrijkste systeemfuncties

1. Gegevensverwerving: De host unit verzamelt real-time sensorsignalen zoals amplitude, hoogte, hoek, gewicht en windsnelheid.

2. Gegevensverwerking: Berekent de koppelwaarde onder de huidige bedrijfsomstandigheden in realtime en vergelijkt deze met vooraf ingestelde hefkarakteristieken, waarbij lokale alarm- en besturingslogica wordt uitgevoerd.

3. Gegevensoverdracht: Verwerkte belangrijke gegevens, alarminformatie en werkingsgegevens worden via een 4G-netwerk in realtime geüpload naar het cloudplatform.

4. Gegevensanalyse: Het platform bewaart en visualiseert verschillende soorten gegevens en biedt verschillende weergaven en rapporten voor verschillende rollen.

5. Alarmen op meerdere niveaus: 1. Vroegtijdige waarschuwing (het bereiken van 90% van de nominale waarde); 2. Alarm (het bereiken van 100% van de nominale waarde, hoorbaar en zichtbaar alarm)

6. Functie voor bediening en onderhoud op afstand: Beheerders kunnen op afstand de status van de apparatuur bekijken en in speciale omstandigheden (zoals zwaar weer) op afstand opdrachten geven om de geleiderails en grijperbakken te bedienen.

Voordelen en waarde

- Verbeterde veiligheid op de site

- Digitale nalevingsbestanden