Edge Data Cleaning is the silent hero of smart manufacturing. While many talk about AI and predictive maintenance, the real challenge on the ground is fundamental: data from PLCs and sensors is often “dirty.” Without cleaning it at the source, even the best algorithms fail.

Issues like data jitter, abnormal spikes, invalid values, and “holes” caused by communication drops are everywhere. If we don’t fix these at the source, even the most advanced backend system will be “forced” to give distorted results. This is why more and more manufacturers are focusing on a step closer to the field: Edge Data Cleaning.

Industrial Data is Rarely “Born Ready”

Data from PLCs and sensors is built for control, not for analysis. Between aging sensors, field interference, and equipment switching, data is constantly fluctuating. What looks “normal” for basic control can be pure “noise” for an analysis system.

If we upload this raw data without processing, we aren’t just uploading numbers—we’re uploading errors. When a project underperforms, the problem usually isn’t the algorithm; it’s the quality of the input.

Why Do Cleaning at the “Edge”?

The old way was to dump everything onto a server and clean it there. But as the scale of equipment grows, so do the costs and risks. The beauty of Edge Computing is that it makes the first “judgment call” right where the data is born. It stops the “obviously unreliable” data at the gate.

Edge cleaning doesn’t replace cloud analysis; it lightens the load for the backend, ensuring data is “business-ready” from the very start.

Edge Data Cleaning: “Understanding Equipment Behavior”

This isn’t just about simple filtering. Take power spikes during equipment startup: they are normal for control logic, but they can ruin an energy consumption analysis. By using edge computing, we can apply different rules based on the machine’s actual status. It’s about making the data “understand” the equipment—something much easier to do when you are physically close to the machine.

Sensors: Guarding Against “Occasional Anomalies”

Sensors often glitch due to poor contact or the environment. If these anomalies are saved in your database long-term, they become part of a “fake trend.” Edge computing identifies these through threshold checks and rate-of-change analysis, correcting or flagging them locally before they “pollute” the entire system.

Stability and Scalability

When data is organized at the edge, the upper-level systems (like MES or SCADA) become much simpler. They deal with a clean, structured stream of information, leading to better stability. From a long-term perspective, this makes scaling easy: you just define the cleaning rules for new devices at the edge, without having to rework your central system constantly.

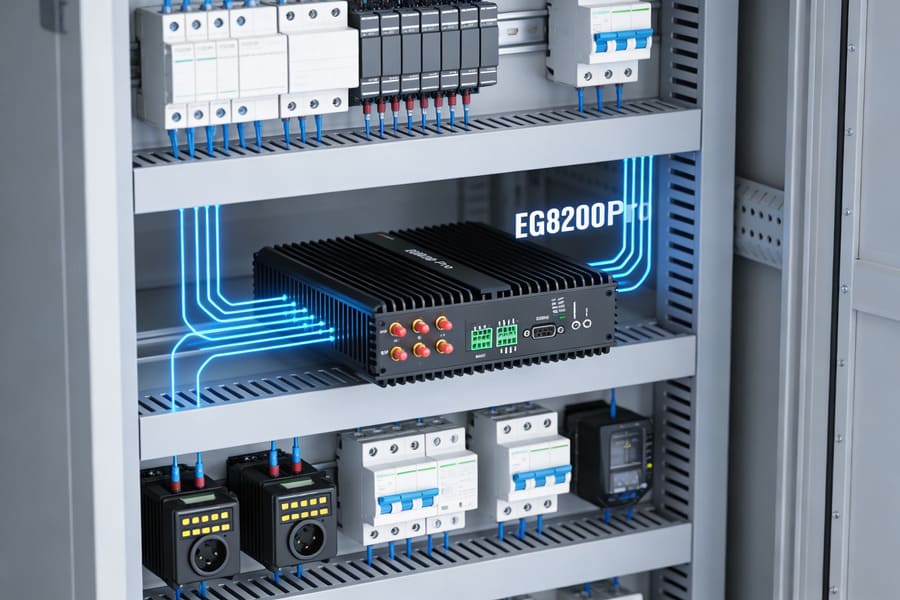

How We Do It at IOTRouter

In our field practices, we treat edge computing devices as the “First Gate” for data quality. We use our stable PLC and sensor acquisition capabilities to handle the basic cleaning and status judgment at the edge.

Our philosophy isn’t just to “compute more,” but to “get the data right first.” This ensures that intelligent analysis is built on a foundation of trust.

FAQ

Q1: Does edge cleaning slow down the system?

With proper configuration, the impact on real-time performance is negligible.

Q2: Do I need to change the rules often?

Usually, it’s a one-time setup with minor periodic tweaks.

Q3: Can I still keep the original raw data?

Absolutely. It can be backed up locally or in the cloud.

Q4: Does this replace cloud analysis?

No, it’s a pre-processing step to make the cloud analysis more accurate.

Sintesi

The foundation of industrial intelligence isn’t how complex your model is, but whether your data is trustworthy. Much like climbing a mountain, you need a solid path to reach the top. By bringing data cleaning to the edge, we control quality at the source, making the whole system more stable and the results more accurate.