Communication is the backbone of the Internet of Things (IoT). Efficient protocols are essential for connecting devices to local controllers or cloud platforms. Two of the most widely used protocols are MQTT and Modbus, each designed for different purposes: MQTT for lightweight, scalable messaging across networks, and Modbus for deterministic, local industrial control.

This article explains the key differences between these protocols, their complementary roles, and how edge gateways can integrate both to enable robust, hybrid IoT deployments.

MQTT Protocol

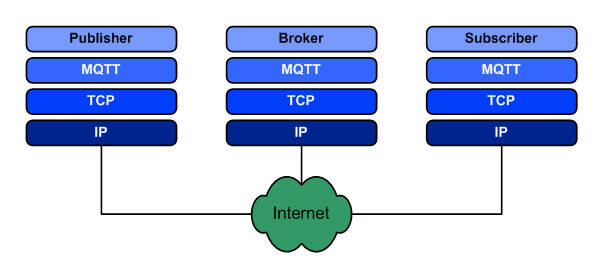

MQTT (Message Queuing Telemetry Transport) is a lightweight, open protocol optimized for machine-to-machine (M2M) communication in IoT. It relies on a central broker that coordinates communication between clients. Clients can act as:

-

Publishers: Sending messages to specific topics

-

Subscribers: Receiving messages from specific topics

Key Features:

-

Lightweight Design: Minimal overhead, ideal for low-resource devices and constrained networks

-

Publish/Subscribe Pattern: Decouples producers and consumers for flexible, asynchronous communication

-

Quality of Service (QoS): Three levels to ensure reliable delivery

-

QoS 0: At most once

-

QoS 1: At least once, acknowledgment required

-

QoS 2: Exactly once, using a four-phase handshake

-

-

Core Operations: CONNECT, DISCONNECT, PUBLISH, SUBSCRIBE, UNSUBSCRIBE

-

Advanced Features: Retained messages, last will messages, dynamic topic subscription, and scalable distributed communication

Modbus Protocol

Modbus is a widely used serial communication protocol in industrial automation and SCADA systems. It follows a master-slave architecture:

-

Master: Initiates requests

-

Slaves: Respond to requests

Originally for RS-232/RS-485 networks, it now also supports TCP/IP connections.

Key Characteristics:

-

Master-Slave Communication: One master can control up to 247 slaves

-

Deterministic Request-Response: Ensures predictable control timing

-

Industrial Focus: Optimized for PLCs, sensors, and actuators

-

Open Standard: Simple, robust, widely supported across industrial networks

Comparing MQTT and Modbus

| Feature | MQTT | Modbus |

|---|---|---|

| Communication Type | Publish/Subscribe | Master-Slave |

| Scope | Global / Cloud / Internet-scale | Local / Industrial networks |

| Device Requirements | Low-resource embedded devices | Industrial controllers and sensors |

| QoS Support | Multiple levels (0,1,2) | Not defined |

| Use Case | IoT data collection, cloud integration | Local industrial control, SCADA |

Key Insight:

Modbus excels in deterministic, local device control, while MQTT enables scalable, low-latency communication across local or cloud networks.

EG8200 Gateway Support for MQTT and Modbus

Edge gateways, such as the EG8200 series, demonstrate how these protocols can be integrated efficiently in hybrid IoT systems.

MQTT Features on EG8200:

-

Publish/Subscribe Nodes: Flexible message routing

-

Multi-Broker Support: Connect to multiple MQTT servers

-

Dynamic Broker & Topic Configuration: Use device SN as client ID for batch deployment

-

Automatic Reconnect & Status Monitoring: Reliable communication in real time

-

Practical Use Case: Sensor or PLC data collected via the gateway can be published to cloud platforms instantly for monitoring, analytics, and hybrid IoT operations

Modbus Features on EG8200:

-

Master Request & Parse Nodes: Configurable by address, function code, register start, and register count

-

RTU/TCP Support: Seamless across serial or TCP networks

-

Flexible Data Types: Bool, Int16/32, UInt16/32, Float32, Double64, String, BCD

-

Optimized Grouping: Multiple registers with same slave/function code grouped for efficiency

-

Practical Use Case: Local deterministic control of PLCs, sensors, and actuators over serial/TCP networks

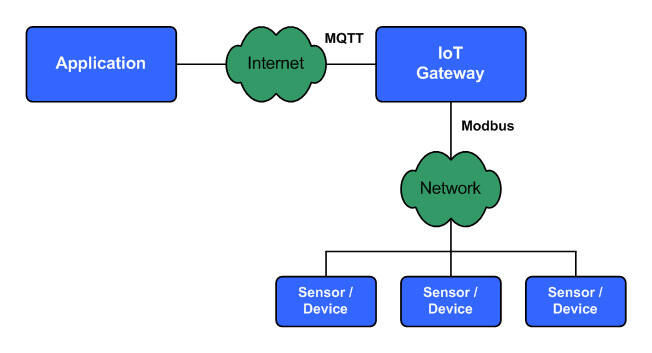

Integrating MQTT and Modbus in IoT Systems

Many IoT deployments benefit from combining the strengths of both protocols:

-

Local Device Management with Modbus: Efficient communication with industrial devices, ensuring predictable, real-time control

-

Global Communication with MQTT: Publish locally collected data to brokers for remote monitoring, analytics, or cloud-based control

-

Seamless Interaction: Data acquired via Modbus can be published in real time through MQTT, supporting hybrid architectures

Practical Example:

A gateway collects sensor data via Modbus, processes it locally, and publishes results via MQTT to a cloud platform. This enables real-time monitoring, analytics, and remote control, while maintaining deterministic local operations.

Key Takeaways

-

Complementary Protocols: MQTT and Modbus operate at different layers; combining them enables full-stack IoT solutions

-

Deployment Flexibility: MQTT supports low-resource, wide-area communication; Modbus ensures deterministic local control

-

Performance Optimization: MQTT QoS guarantees delivery; Modbus ensures predictable industrial responses

-

Future-Proof Design: Mastery of both protocols allows scalable IoT systems from single-site deployments to global networks

FAQ

Q1: What is the main difference between MQTT and Modbus?

A: MQTT is lightweight, suitable for global IoT messaging. Modbus is master-slave, ideal for local industrial control.

Q2: Can MQTT and Modbus be used together?

A: Yes. Modbus manages local devices, while MQTT extends connectivity to cloud or wide-area networks.

Q3: Which protocol is faster?

A: MQTT is faster for wide-area, low-bandwidth communication. Modbus is optimized for local deterministic control.

Q4: Which devices use MQTT and Modbus?

A: MQTT is for embedded devices, gateways, and IoT endpoints. Modbus is for industrial controllers, sensors, and SCADA systems.

Q5: Why is understanding both protocols important?

A: Developers can design IoT systems that balance reliable local control with scalable global connectivity.

Conclusion

MQTT and Modbus are cornerstones of modern IoT architecture. Integrating both enables hybrid systems that:

-

Maintain deterministic local control via Modbus

-

Provide scalable, efficient global communication via MQTT

Edge gateways, like the EG8200 series, illustrate how practical deployments can bridge local and cloud networks, ensuring real-time control, monitoring, and analytics. Understanding and leveraging both protocols helps engineers maximize IoT performance, reliability, and scalability for today’s and future connected environments.