After 3 months of hard work, we are very pleased to announce the release of the new EG8200Mini-104 Edge Computing Gateway!

Based on the EG8200Mini gateway, this product combines the IEC104 protocol to further enhance the data acquisition and protocol conversion capabilities. The EG8200Mini is a hot-selling product of IOTRouter, which has been sold in many regions all over the world in 2024, and has been widely acclaimed by customers. The design concept of the EG8200Mini-104 still revolves around “professionalism, dedication, and innovation” to provide users with more flexible and innovative edge computing gateways.

Features of the EG8200Mini-104

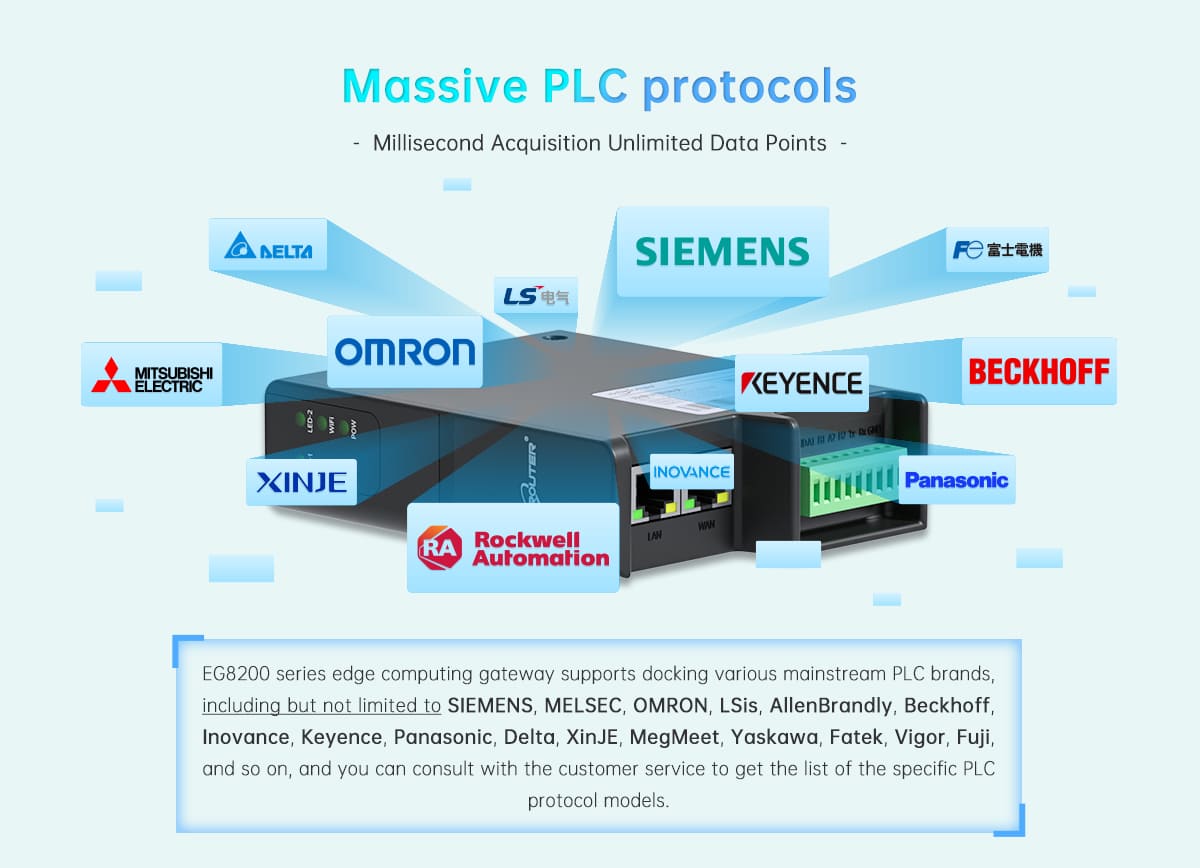

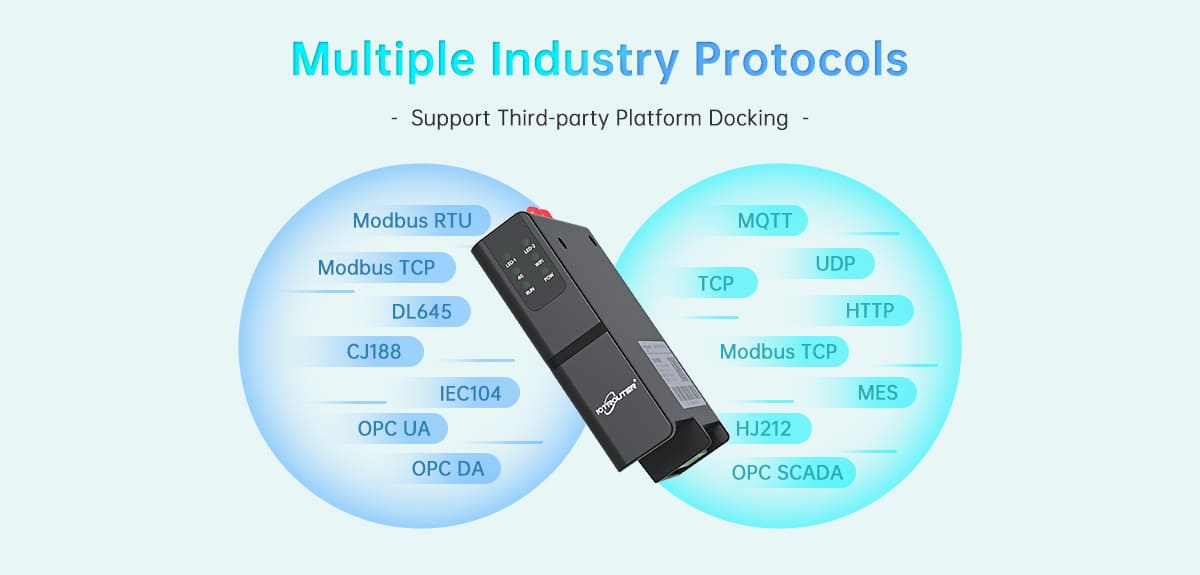

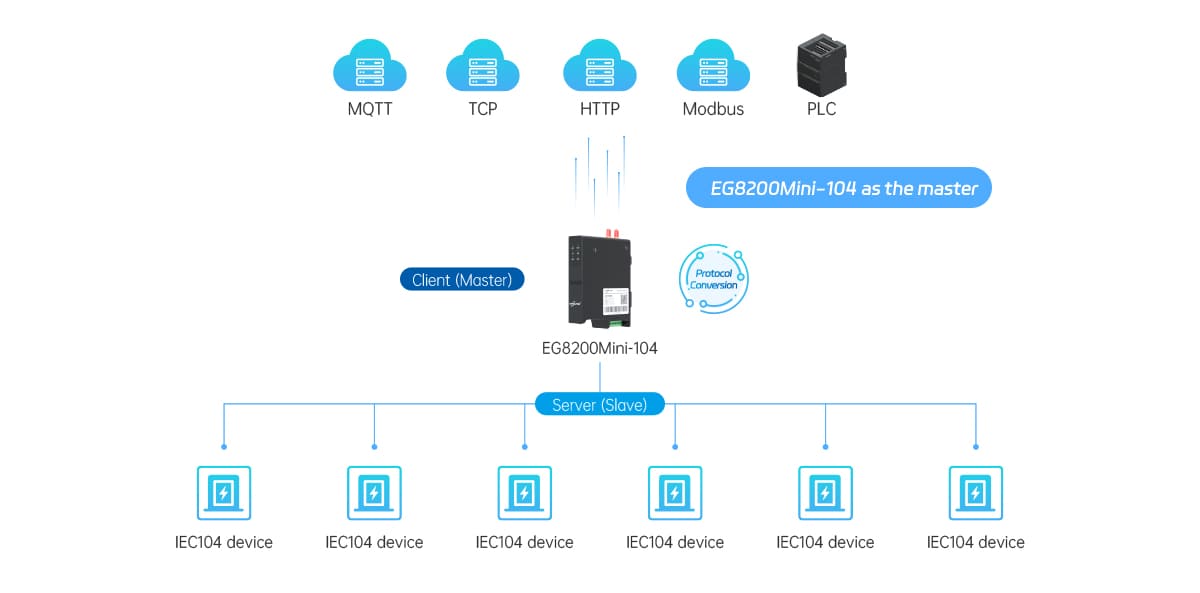

1. Multi-protocol compatibility, breaking the device island

As a master or a slave, EG8200Mini-104 supports IEC104, Modbus RTU/TCP, DLT645, BACnet and other mainstream industrial protocols. It can be seamlessly connected to PLCs, CNCs, meters, serial devices and all kinds of sensors. Its unique advantage lies in its compatibility with dozens of brands such as Siemens, Mitsubishi, Omron, Huichuan PLC protocol. Solve the data acquisition problems under the coexistence of multi-brand equipment. Through the protocol conversion function, the data of devices with different interfaces (network port, RS485/232) can be uniformly converted into common protocols such as MQTT, HTTP, TCP, etc., which can be directly docked to cloud platforms or third-party systems to realize the interconnection and interoperability of heterogeneous devices.

2. Remote Operation and Maintenance and Virtualization, Enhancing Management Efficiency

With the supporting EGManager software, users can remotely complete equipment configuration, program update and troubleshooting, breaking through the physical space limitations. For example, through the function of “remote virtual serial port”, engineers can debug serial port devices without arriving at the site. The virtual LAN built with VPN technology supports PLCs to remotely download programs, significantly reducing operation and maintenance costs. For distributed deployment of energy meters, environmental monitoring equipment, etc., this function can quickly respond to abnormalities and ensure system continuity.

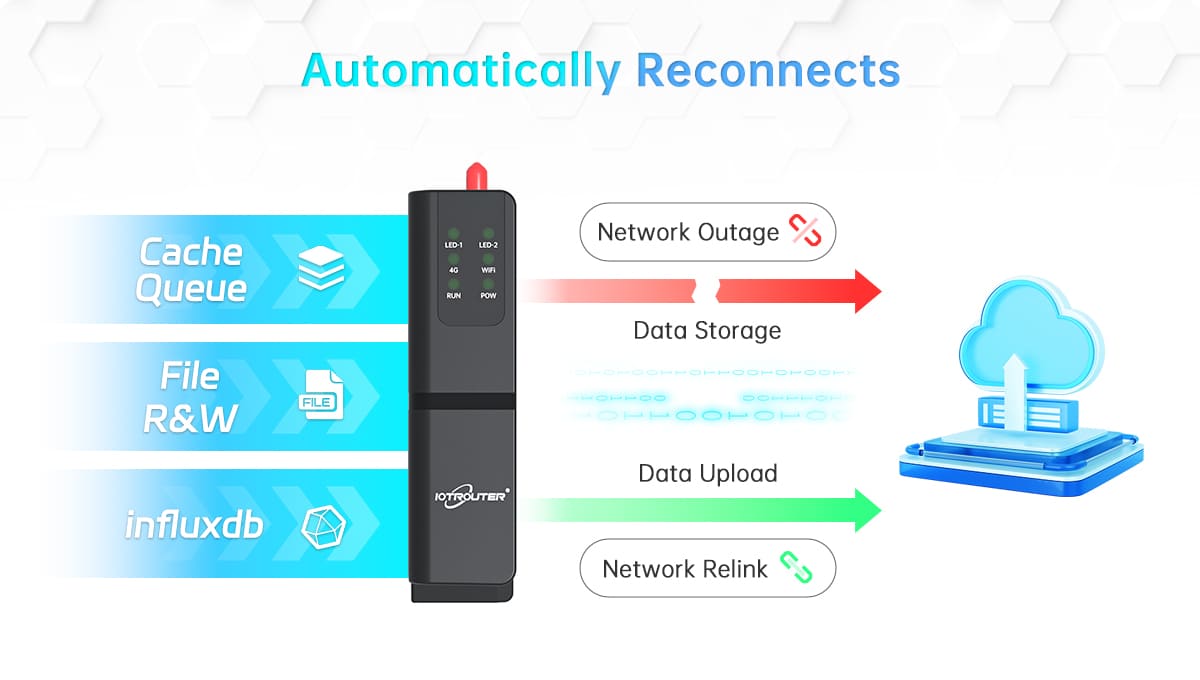

3. Network redundancy and data toughness to ensure stable operation

The gateway supports 4G, wired network, WiFi multi-link access, and intelligent switching between main and backup networks to ensure continuous online in outdoor or complex industrial environments. During network disconnection, local data is automatically cached and re-transmitted to avoid loss of critical data. Combined with the maximum 128GB SD card expansion capability, it is suitable for long-term offline storage scenarios, such as pump station monitoring in remote areas or mobile vehicle data collection.

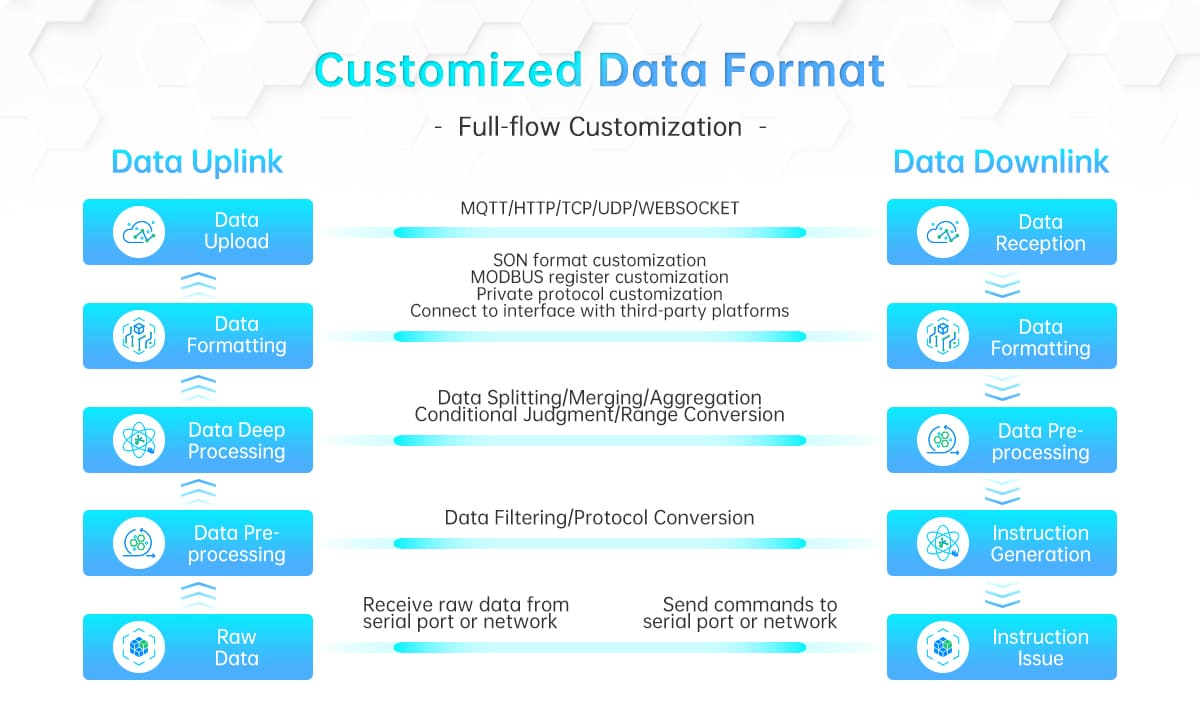

4. The whole process of data customization, flexible adaptation to business needs

From data collection, formatting to forwarding, the gateway supports full process customization. Users can define the packet structure in JSON format or configure the Modbus register mapping relationship on demand to easily interface with third-party platforms such as MES and SCADA. For private protocol devices, the built-in drag-and-drop logic editor supports customized data parsing rules. Splitting, aggregation and pre-processing of data can be realized without coding. Meet the customized needs of intelligent manufacturing, intelligent buildings and other scenarios.

5. Edge computing empowers real-time response

Another core capability of EG8200Mini-104 is to complete parsing and processing at the data source. It supports millisecond data acquisition, and combined with the edge computing function, it can perform operations such as range conversion and condition judgment in real time to reduce the load on the cloud. For example, it can directly filter invalid data and trigger alarms in production lines, or complete local summarization of meter data in energy management to improve system response efficiency.

Applicable Industry Scenarios

Industrial manufacturing: centralized data collection of multi-brand PLCs to achieve equipment status monitoring and energy efficiency analysis.

Intelligent Energy: Remote reading of electricity meter (DLT645/CJ188 protocol) data, supporting unattended operation of photovoltaic power stations and power distribution rooms.

Intelligent building: HVAC and lighting equipment are integrated through BACnet protocol to build building automation system.

Environmental monitoring: outdoor sensor data is transmitted back via 4G network, and data integrity is guaranteed by network disconnection.

Transportation operation and maintenance: mobile vehicle equipment through VPN remote maintenance, reducing the frequency of on-site maintenance.

The EG8200Mini-104 Edge Computing Gateway centers on protocol compatibility, remote management, and data toughness. It provides a lightweight and highly reliable connectivity solution for industrial IoT. Its value lies not only in the stacking of technical parameters, but also in the ability to break down equipment barriers and simplify the operation and maintenance process in actual scenarios. This makes it an indispensable infrastructure in digital transformation.

We invite you to discover the new possibilities offered by the EG8200Mini-104. Together, let’s explore the future of IoT, drive industry transformation, and support your business growth!