The intelligent manufacturing industry is becoming a global trend and a focus for Chinese enterprises. In the past few years, China’s intelligent manufacturing industry has maintained a rapid growth rate, with an average growth rate of more than 20%. With policy support and industry trends, many Chinese companies have begun to promote intelligent strategies. In addition to Midea, Gree, Haier, Huawei and other technology companies that are increasing their investment, companies in various industries such as clothing and FMCG are also beginning to enter the market.

According to industry insiders, smart manufacturing represents a new round of industrial revolution, and China has unique advantages in this revolution. With the continuous promotion of leading enterprises in various industries, if China can seize its own cost, market, and technological advantages, it will have the opportunity to overtake in this revolution and gain the upper hand.

The new industrial revolution is a major historic opportunity for our country to realize the transformation of old and new driving forces and promote high-quality economic development. Driven by the new industrial revolution, China has achieved remarkable results in cultivating new drivers of economic development. Technological innovation capabilities, industrial innovation capabilities, corporate innovation capabilities, and product innovation capabilities are all constantly increasing. China is accelerating its transformation from an economic power to an economic power.

Intelligent manufacturing is “gestating”

Voice recognition, face recognition, driverless driving, mobile payment… With the widespread use of smart technology, the smart industry is developing rapidly and is becoming a new engine of economic development and an accelerator of social development. Public information shows that from 2010 to 2017, my country’s intelligent manufacturing industry maintained a rapid growth rate. In 2017, the output value of my country’s intelligent manufacturing industry exceeded RMB 1 trillion. Overall, the average growth rate over the past eight years has reached more than 20%. Intelligent manufacturing will play a more important role in my country’s manufacturing industry in the future.

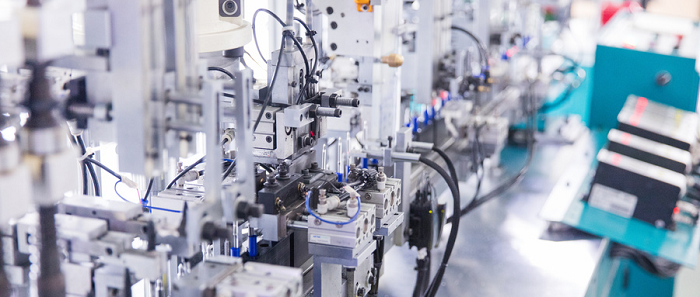

It is understood that smart manufacturing mainly transforms and upgrades the traditional manufacturing industry through the industrial Internet of Things, industrial Internet, industrial software systems, industrial robots, etc., solving the problem of siled industrial equipment data, insufficient production process informatization, lag in overall management, and labor costs. Issues such as rising year by year. The development of intelligent manufacturing has driven the application of technologies such as the Internet, big data, and artificial intelligence in the manufacturing field, forming a variety of new business formats and models such as mass customization, network collaborative manufacturing, and remote operation and maintenance services.

Currently, a variety of typical new smart manufacturing models are being promoted and applied, which has significantly accelerated the pace of industrial upgrading. Driven by intelligent manufacturing projects, emerging industries such as industrial robots, additive manufacturing, and industrial sensors have developed rapidly. In 2017, the output of industrial robots exceeded 130,000 units/set, a year-on-year increase of 68.1%. The market size accounts for approximately one-third of the world’s total, and it has become the world’s largest application market for five consecutive years. The total scale of the additive manufacturing industry increased from 5.5 billion yuan in 2015 to more than 10 billion yuan in 2017, with an average annual growth rate of more than 30%.

Wang Xiaohong, deputy director of the Information Department of the International Economic Exchange Center, said that technologies such as 5G and the Internet of Everything have triggered a new generation of industrial revolution, and smart manufacturing is actually a disruptive change in the traditional manufacturing industry brought about by the new generation of network digital connectivity technology. The future manufacturing industry will greatly reduce human operations, and enterprises will also transform from labor-intensive to capital-intensive. In addition, smart manufacturing has also brought about fundamental changes in methods. Traditional industries are large-scale standardized operations, but driven by smart manufacturing, today’s industries can form personalized customization through big data and cloud platforms.