In many smart manufacturing projects, the real bottleneck isn’t that the algorithms are not advanced enough, or that the systems lack features—it’s a seemingly basic, yet unavoidable problem: devices simply can’t talk to each other.

Old machines, new production lines, and control systems from different vendors coexist, each using its own protocol, with inconsistent data standards. Industrial IoT often can’t connect on the shop floor, making any further analysis or optimization almost impossible.

It is in this context that edge protocol conversion and edge computing gradually become key players. They may not be visible, but they decide whether the system can actually run.

The Reality of Protocols on the Shop Floor

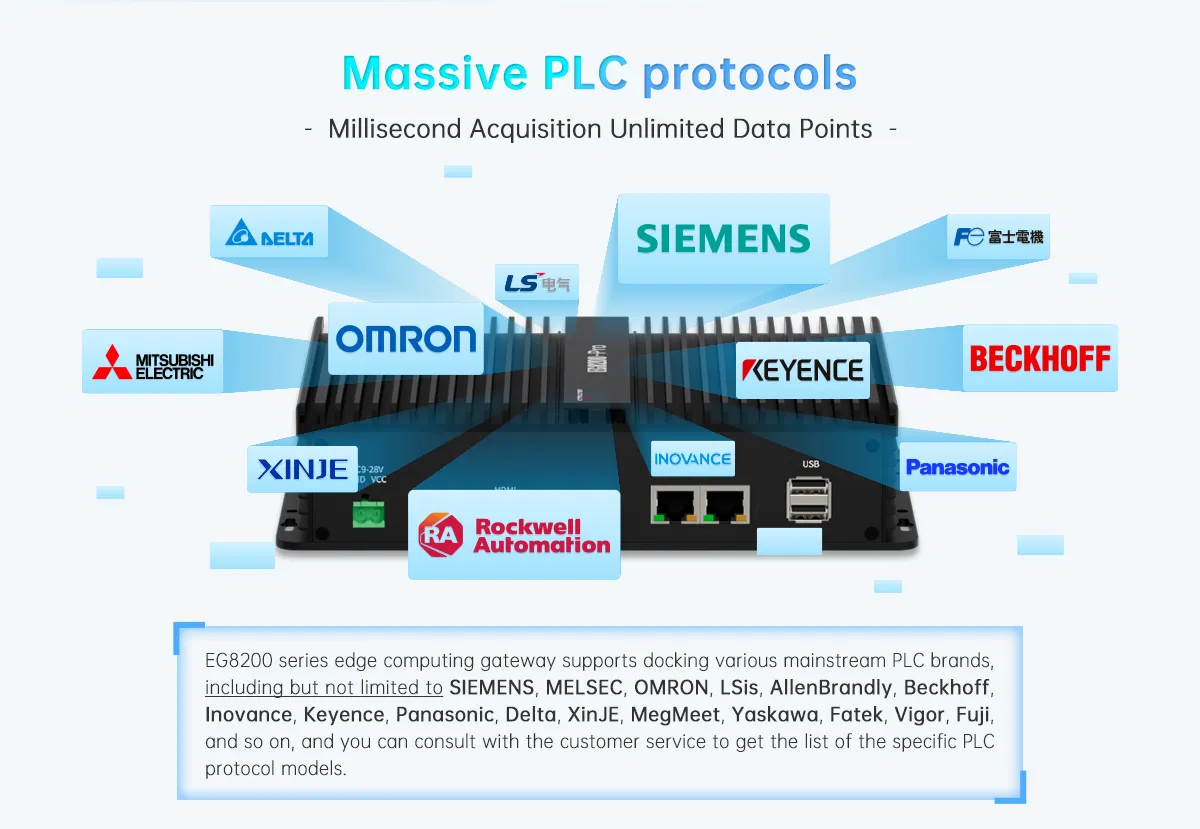

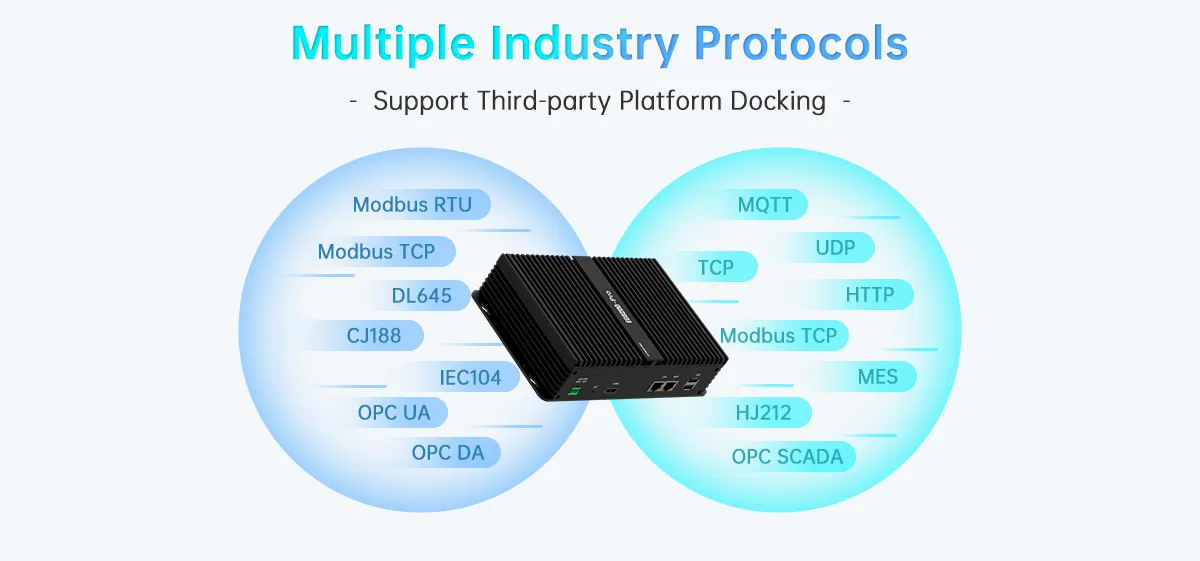

In any mature factory, you will find a very complex protocol environment. PLCs may be from multiple brands; devices might use Modbus, Profibus, CAN, or EtherCAT; and upper-level systems often expect OPC UA, MQTT, or HTTP interfaces.

And that’s before you even consider legacy machines with private protocols. A naturally unified system? Almost nonexistent.

If all protocol conversion is handled by a central server or the cloud, not only is latency high, but debugging becomes infinitely more costly. Many projects get stuck here, ending up with a “collect what we can” approach.

Edge Protocol Conversion Keeps Complexity Local

The core value of edge protocol conversion is that it leaves protocol complexity at the device side. Edge gateways or edge computing nodes connect directly to devices, understand the local “language,” and output standardized data upward.

The benefits are clear:

1) Upper systems no longer need to care about which device or protocol is used—they just handle unified data.

2) MES, SCADA, and industrial IoT platforms face lower integration barriers.

3) From an engineering perspective, this step is often even more critical than moving data to the cloud.

When Protocol Conversion Meets Edge Computing

If protocol conversion solves “can we connect?”, edge computing solves “once connected, what do we do with the data?”

Performing data preprocessing, status checks, and simple logic locally can significantly reduce unnecessary data uploads. For example, data is only reported when device status changes, parameters go out of range, or cycle times are abnormal—rather than sending all raw points.

This not only reduces network load but also ensures that upper systems receive data that has actual operational meaning.

Protocol Conversion Is More Than Field Mapping

Many people think protocol conversion is just “field-to-field” mapping. In real projects, semantic alignment matters more. Different devices may define the same status differently; even the same vendor’s devices from different eras can have different data meanings.

Edge nodes can perform data reconstruction, transforming raw register values into unified operational states, alarm levels, or process parameters. This step often determines whether subsequent analysis is reliable.

Edge Architecture Makes Systems Flexible

In an evolving smart factory, production lines are adjusted, devices are replaced, and protocol environments continue to change. Putting protocol adaptation at the edge significantly reduces overall system modification costs.

Adding a new device only requires adaptation on the edge side; upper systems hardly need any changes. This decoupled structure is especially important for factories that need to run long-term.

IOTRouter’s Approach to Edge Protocol & Computing

In practice, IOTRouter treats edge devices as the “shop floor data hub”. By supporting multiple protocols, flexible data mapping, and local computing capabilities, data is organized and preliminarily analyzed as close to the devices as possible.

This approach doesn’t aim for a one-time, large system. Instead, it emphasizes scalability and maintainability, keeping industrial IoT running stably in complex shop floor environments.

FAQ

Q1: Why not replace all devices with a single protocol?

A1: The cost and risk are too high.

Q2: Will edge protocol conversion affect real-time performance?

A2: With proper design, it can actually improve speed.

Q3: Does the data model need to be defined all at once?

A3: It can evolve gradually.

Q4: How is edge node stability ensured?

A4: Industrial-grade hardware is essential.

Conclusion

Industrial IoT truly takes off from the shop floor, not the cloud. Edge protocol conversion solves the language problem between devices, and edge computing gives data value right at the source. Together, they allow smart manufacturing systems to connect seamlessly and run reliably.

These seemingly “basic” capabilities are actually the foundation for the long-term evolution of smart factories.