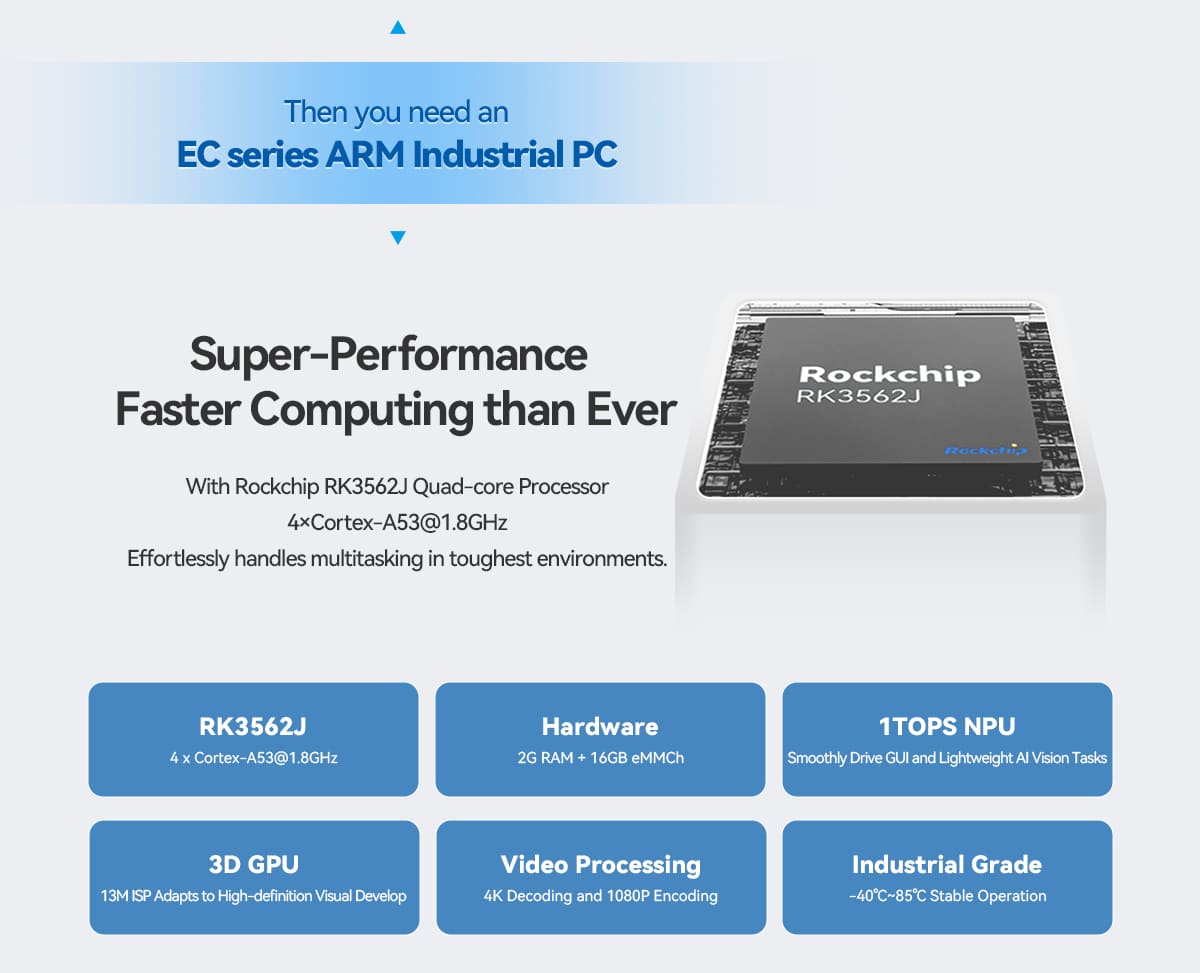

EC300 ARM Industrial Computer Available! IOTRouter’s newly launched EC300 high-performance ARM industrial computer is equipped with Rockchip’s RK3562J(4×Cortex-A53@1.8GHz) processor.

It is suitable for the quick developing your own iot gateway. You can define your protocals and the functions of the gateway via the covinient programming method and feel free to obtain the quick and safe developing.

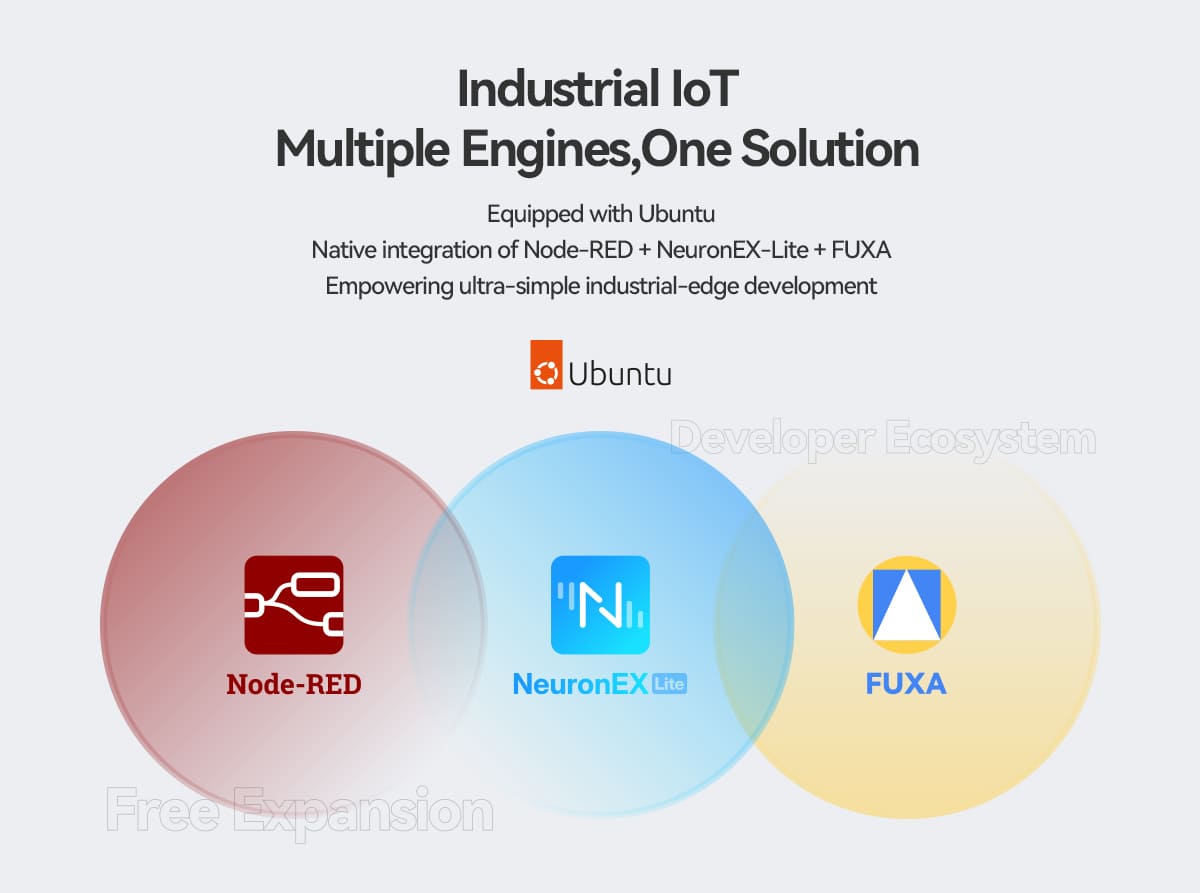

This device supports AI vision and 4K video decoding, comes pre-installed with the Embedded Linux operating system, and natively integrates Node-RED, NeuronEX-Lite, and FUXA, targeting data acquisition, edge computing, and field control scenarios.

Key features and specifications

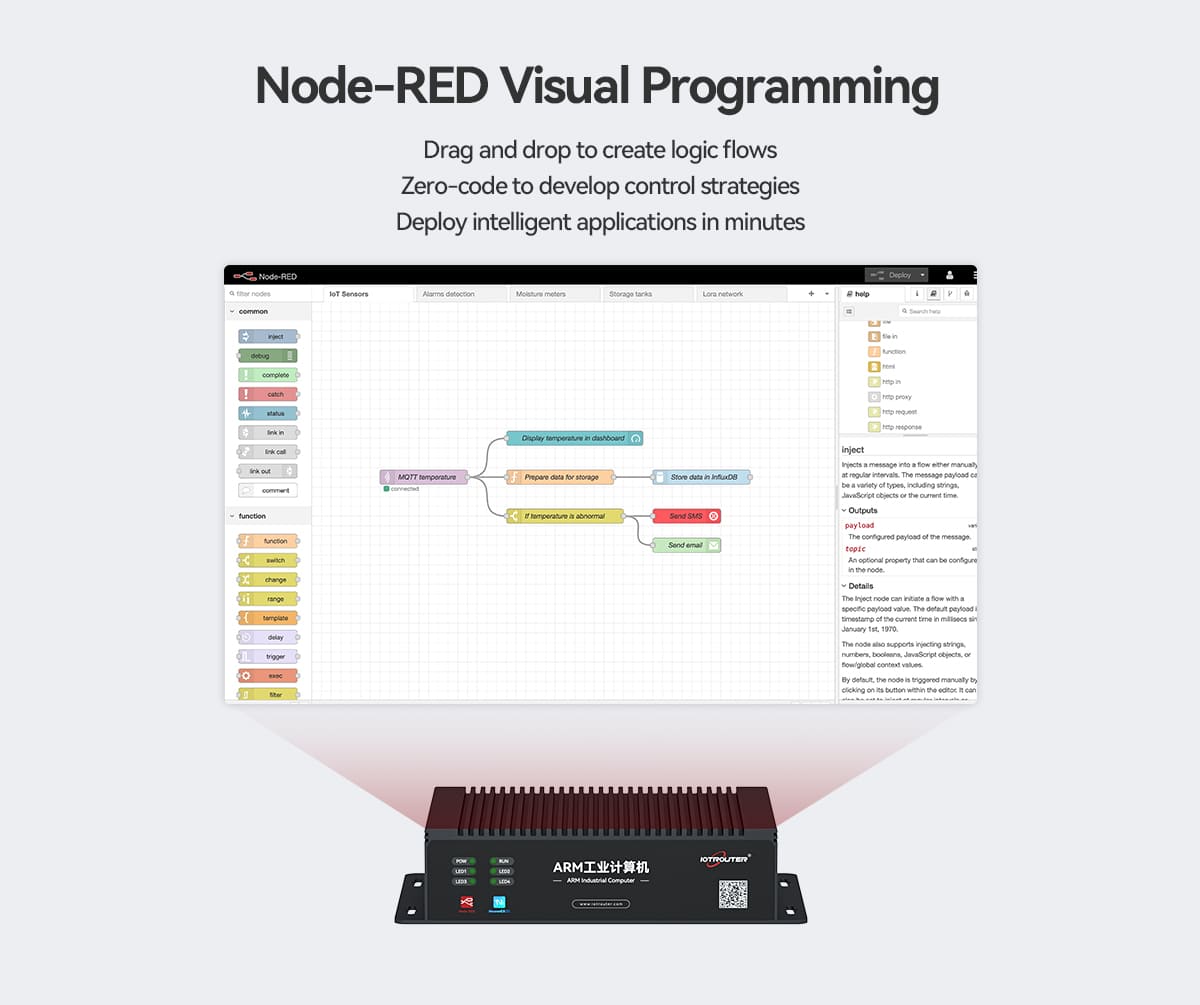

1. Node-RED: Drag-and-drop logic, zero-code development;

2. NeuronEX-Lite: Supports over 100 protocols(Modbus, PLC, 104, etc.);

3. Unified access via FUXA: Zero-code configuration, rapid visualization;

4. Industrial interfaces: RS485/RS232/CAN, etc.;

5. Multi-network collaboration: 5G/4G/Ethernet/Wi-Fi;

6. Audio-visual integration: HDMI large screen + audio alerts

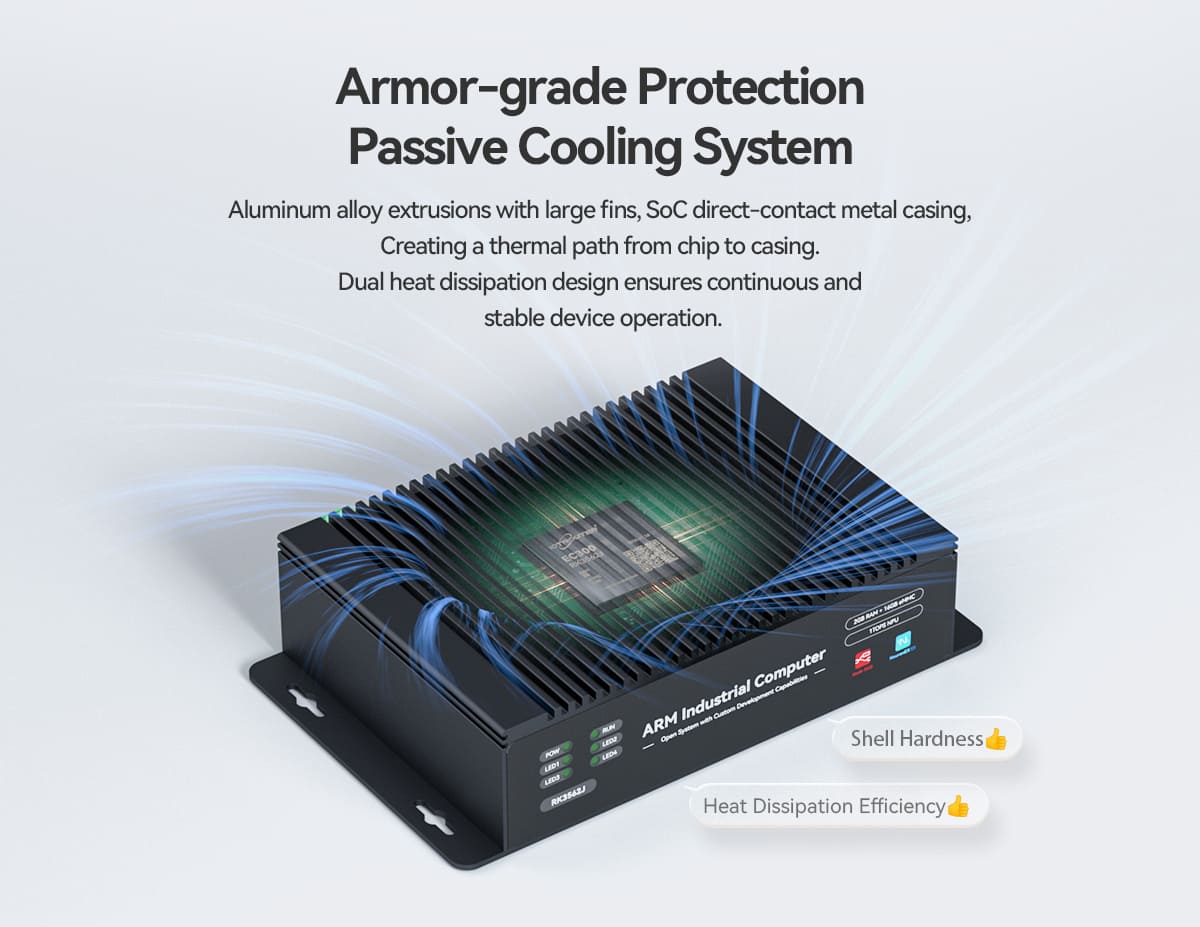

7. Passive cooling: Aluminum alloy housing for stable operation

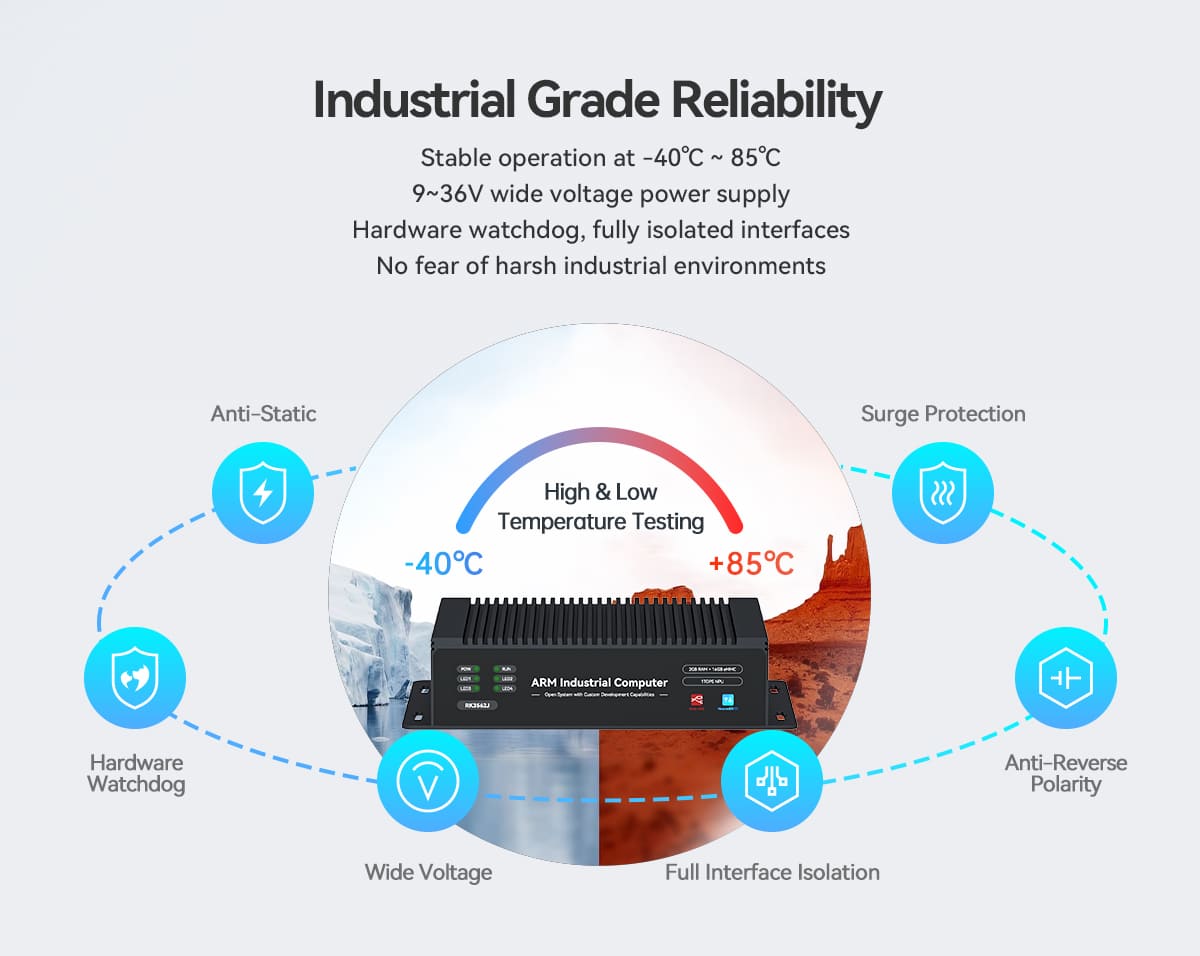

8. High reliability: Wide temperature and voltage range, hardware watchdog

9. Electrical protection: Interface isolation, anti-static surge protection

10. Operations management: Remote configuration, debugging, and firewall management

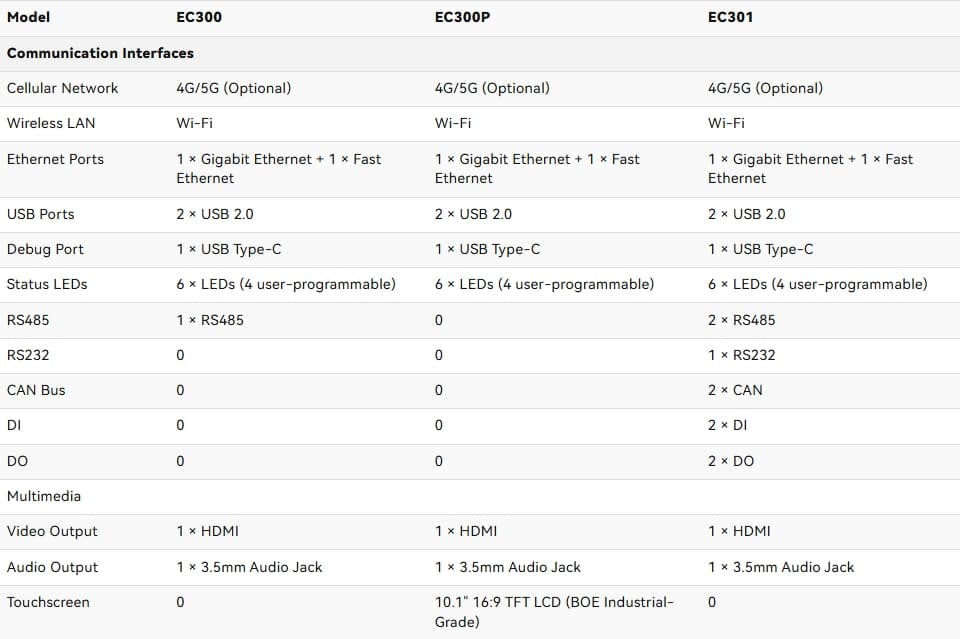

Available Versions

This EC300 series ARM industrial PC supports 3 versions:

1.EC300 (Standard): RS485 x 1, 100/1000 Mbps LAN/WAN Ethernet port, 2 x USB. Cost-effective for data acquisition and edge computing.

2.EC300P (Touchscreen): 10.1-inch BOE industrial-grade display + Audio. Supports touch-enabled HMI for on-site monitoring.

3.EC301 (Multi-Interface): Enhanced industrial bus interfaces (Dual CAN, Dual RS485) + I/O control (2x DI / 2x DO). Suitable for automated production lines.

Development

EC ARM Industrial Computer Development Guide

With EC series products, you can develop:

Special protocols, such as PLC protocols, 104 protocols, etc.;

Business functions and logical judgments;

Data processing methods and data transmission, etc.;

Remote management, remote upgrades, remote control, etc.;

Other functions.

Application Scenarios

The EC300 is an open-source programmable gateway that provides users with a great deal of creative freedom. Traditional enterprises are facing the challenge of transitioning to intelligent and automated operations. The EC300 is ideally suited to assist manufacturing enterprises in quickly establishing protocol connectivity, data monitoring, and remote control capabilities, thereby helping enterprises to rapidly upgrade their operations.

1. Smart Manufacturing and Industrial Automation

On production lines, various manufacturers use a multitude of device protocols. With the built-in NeuronEX-Lite protocol stack in EC300 (supporting PLC, Modbus, 104, and other industrial protocols), you can easily connect various production equipment. Real-time collection of critical data and remote control are achieved.

Even if a company lacks professional developers, that’s no problem. Using the EC300’s built-in Node-RED no-code platform, companies can independently develop and quickly build automated workflows. For example, device status monitoring, alarm triggering, and production efficiency analysis can be implemented to achieve smart manufacturing upgrades.

2. Smart Buildings and Building Automation

The EC300 supports a wide range of hardware interfaces, such as RS485/RS232/CAN interfaces. Through these interfaces, the EC300 can be integrated into building control systems (lighting, air conditioning, security). In conjunction with the FUXA visualization management platform, managers can remotely monitor and adjust device status, achieving energy optimization and centralized management.

3. Video Surveillance and AI Edge Recognition

In the application of video surveillance and AI edge recognition in digital factories and digital buildings, the EC300 plays an important role. The EC300 supports 4K video decoding and AI visual processing, enabling video image analysis and event alarms.

4. Transportation and Smart Logistics

Thanks to the EC300’s excellent multi-network connectivity (5G/4G/Wi-Fi/Ethernet) and its wide temperature design (-40°C to 80°C), it can ensure long-term continuous and stable operation, making it suitable for on-site monitoring and edge AI computing.

Through remote upgrade and remote control functions, logistics companies can monitor vehicle status, cargo temperature and humidity, and transportation routes in real time, improving scheduling efficiency and operational safety.

EC300 ARM Industrial Computer Available!

The EC300 series ARM industrial computers combine high-performance processors, rich interfaces, flexible development platforms, and remote management capabilities, making them an ideal choice for industrial IoT gateways, edge computing, and automation control scenarios. The EC300 provides stable and reliable industrial-grade solutions to help businesses achieve digital transformation and intelligent upgrades.

Related Article: EC100 ARM Industrial Computer Development Guide