Digital twins are often associated with 3D models, dashboards, or animated simulations—the visible parts of the system. However, their real value comes from continuous, accurate data collection. Without this, a digital twin is like a city with gleaming skyscrapers but no inhabitants: visually impressive, yet disconnected from reality.

To turn digital twins from simple visualization tools into decision-making engines, factories need reliable, real-time data. Delays, inconsistencies, or incomplete data prevent even the most advanced interface from delivering actionable insights, leaving the twin disconnected from the production environment.

1. Why Digital Twins Without Data Are Just Empty Shells

Real-Time Data is Essential

A digital twin is a high-fidelity mirror of the physical world. Its value depends on synchronization. Without a consistent flow of data, the twin becomes static, unable to respond to changes or support predictive operations.

Data Acquisition as the Factory’s Sensory System

Data acquisition captures real-time states across all equipment. The digital twin acts as the processing unit, analyzing these signals to detect anomalies, forecast trends, and optimize operations.

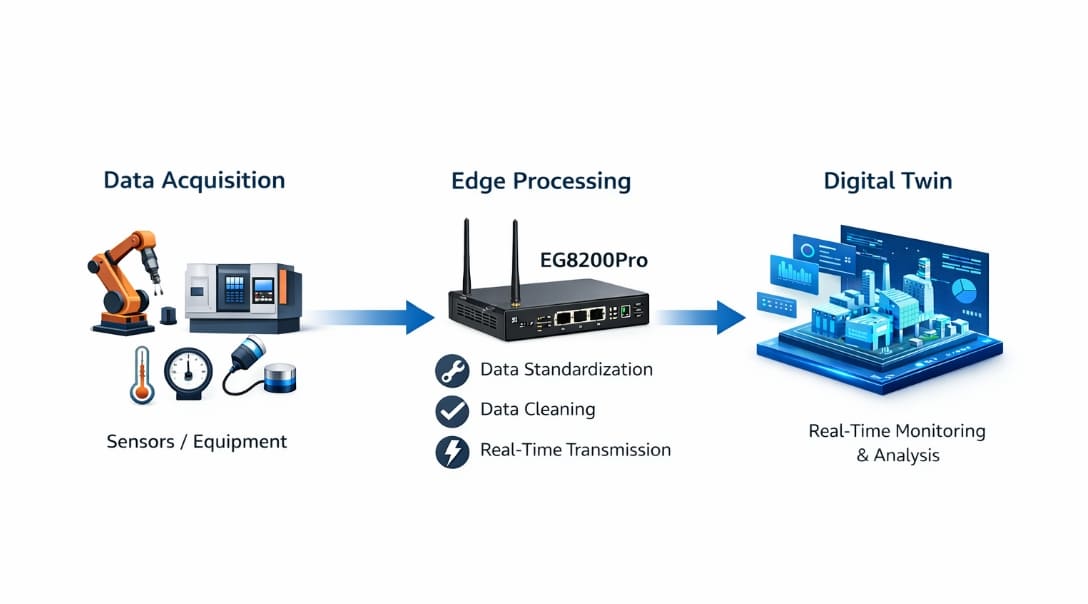

1.EG8200Pro gateways ensure that data from multiple devices—CNC machines, injection molding units, and robots—is standardized, cleaned, and transmitted in real time.

2.By maintaining continuous, accurate input, the twin can reflect equipment status, predict potential issues, and support decision-making.

Industry Insight: Studies indicate that digital twins with reliable, real-time data can reduce unplanned downtime by 15–30% and improve operational efficiency by 20–30%. While these numbers vary by factory, EG8200Pro ensures the data quality necessary to achieve these benefits in practice. (MDPI, 2022)

2. Building a Continuous Sensing Chain: The Key to Effective Digital Twins

Challenges of Direct Device Integration

Factories often contain diverse devices with multiple protocols (PLC, CNC, sensors, Modbus, Ethernet, RS-485). Connecting them directly to a digital twin platform can lead to inconsistent data intervals, mismatched formats, and unreliable readings.

Edge Computing Gateways Ensure Data Quality

A robust solution is preprocessing data at the edge before it reaches the twin. Key functions include:

1.Data Standardization: Ensures all devices “speak the same language.”

2.Data Cleaning & Validation: Removes anomalies and fills missing values.

3.Real-Time Assurance: Updates are reflected in the twin within seconds.

This continuous sensing chain guarantees that the digital twin receives clear, reliable signals, enabling accurate monitoring and timely decision-making.

3. What Digital Twins Can Achieve with High-Quality Data

Real-Time Equipment Status Mapping

With high-quality data, digital twins do more than display values—they predict future behavior. Spindle temperatures on CNC machines, press load cycles, and robot joint positions can be monitored for preventive maintenance.

Bidirectional Verification of Process Models

Real-world data constantly validates simulation models, creating a self-calibrating loop. This improves model accuracy and ensures that predictions remain aligned with actual operations.

Early Anomaly Detection

Deviations from expected ranges are immediately visible. Engineers can address issues before alarms trigger, reducing downtime and production risks.

Factory-Level Collaborative Analysis

Aggregated data reveals correlations invisible at the individual machine level, such as:

1.Line-to-line interference

2.Environmental effects on process quality

3.Operator-induced variations impacting output

These insights support comprehensive operational optimization.

4. The Evolution: From Single-Machine Twins to Multi-Layered Digital Twins

Machine to Production Line Twins

Integrating multiple devices enables synchronization and optimization across production lines, improving efficiency.

Production Line to Workshop Twins

Expanding digital twins to the workshop level allows holistic modeling of operational performance, not just isolated lines.

Workshop to Supply Chain Twins

Digital twins can extend upstream to order planning and downstream to logistics execution, creating a comprehensive view of the production ecosystem.

The key driver is robust, continuous data acquisition, not increasingly complex models. The larger the twin ecosystem, the stronger the data foundation—and EG8200Pro provides that foundation by reliably connecting diverse devices to the digital twin.

5. Common Questions About Digital Twins

Can Digital Twins Function Without 3D Models?

Yes. State- and behavior-driven twins are often more critical than visualizations for monitoring and decision-making.

Must Digital Twins Be Cloud-Based?

Not necessarily. Sensitive industries such as medical or semiconductor manufacturing often use edge + local network solutions for security and real-time performance.

What if Data Is Unstable?

Digital twins can still operate, but predictions may be less accurate. Preprocessing and validating data at the edge improves stability before integration.

Which Devices Are Most Suitable for Digital Twins?

Machines with cyclical behavior and clear operational states—like CNC machines, injection molding units, industrial robots, and assembly lines—are ideal.

Conclusion: Digital Twins as Your Factory’s Second Brain

Integrating data acquisition with digital twins ensures every real-world state is accurately represented, instantly reflected, and continuously evolved in the virtual environment. EG8200Pro gateways serve as the bridge between the physical and digital worlds, delivering data reliably, directly, and efficiently. This allows manufacturers to operate a fully controllable, second factory in the virtual space.