Industrial protocol gateways have emerged in response to market demand. In industrial settings, the question isn’t whether protocols exist, but whether your equipment can connect devices from different manufacturers, generations, and tiers—and transform raw data into actionable insights.

The industrial protocol gateway claims to “support the most comprehensive range of PLC and industrial protocols.” This is not merely a list of protocol names in a brochure, but rather a commitment to delivering tangible value on the project site—optimizing engineering workflows, simplifying operations and maintenance, and enabling the system’s long-term evolution.

Why is “broad protocol coverage” crucial for enterprises?

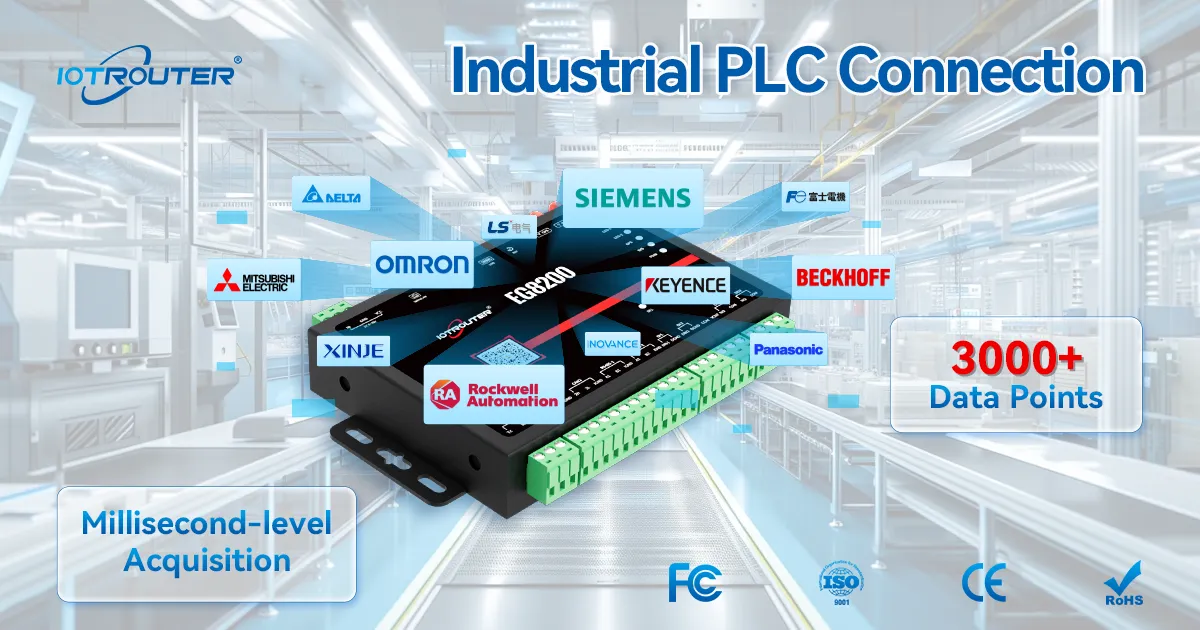

Industrial workshops commonly feature equipment from diverse manufacturers like Siemens, Mitsubishi, Omron, Rockwell (Allen-Bradley), Schneider, and Delta. The communication protocols used by these devices are often incompatible.

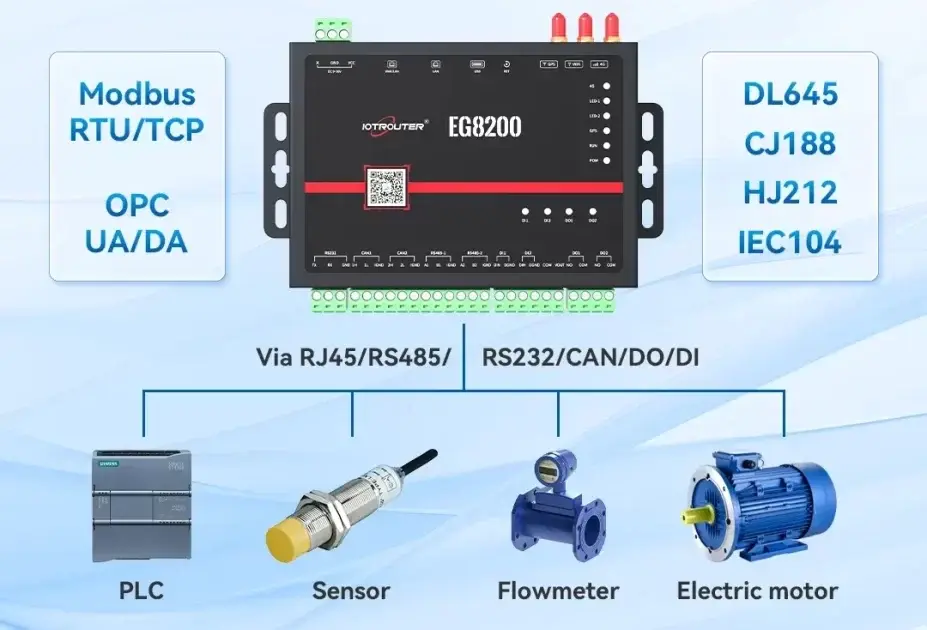

EG8200 Industial protocol gateway

Why use industrial protocol gateway?

Reduce on-site adaptation costs: A single gateway or platform supporting multiple protocols minimizes the need for external converters and reduces secondary development and adaptation work at the site.

Accelerate system integration: When protocols are directly parsed and mapped to a unified data model, upper-layer MES/IIoT/SCADA platforms integrate significantly faster with more consistent data semantics.

These are tangible benefits directly felt during project implementation—not empty slogans, but real improvements in engineering efficiency and operational costs.

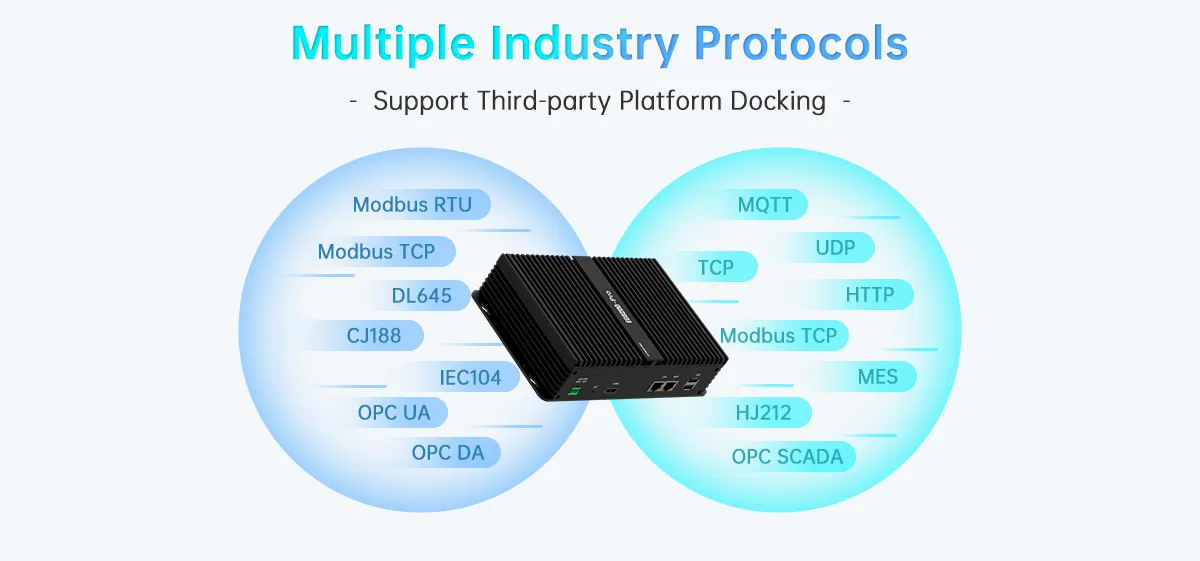

Protocols we typically need to support (listed by category for engineering planning):

Below are typical and common PLCs and industry/communication protocols covering control layer, fieldbus, industrial Ethernet, process and power, building automation, and IoT levels:

1. PLC and Control Systems (Common Vendor Protocols)

Siemens: S7 Communication (S7-comm), Profinet/Profibus (for Siemens PLCs and fieldbus)

Mitsubishi: MELSEC (MC Protocol, MC TCP)

Omron: FINS (Ethernet FINS)

Rockwell/Allen-Bradley: EtherNet/IP, DF1, CIP (Common Industrial Protocol)

Proprietary protocols from Schneider, Delta, Panasonic, etc. (commonly based on Modbus or proprietary messages)

2. Serial Ports / Fieldbus and Real-Time Buses

Modbus RTU / Modbus TCP (extremely common serial and Ethernet protocols)

Profibus (classic fieldbus)

CANopen, DeviceNet (CAN-based fieldbuses)

CC-Link (common industrial bus in Japan/Asia-Pacific)

EtherCAT (high-performance real-time Ethernet)

EtherNet/IP (Rockwell ecosystem)

Fieldbus Foundation (commonly used in process control)

3. IIoT / Upper-Layer Interconnectivity and Standardized Interfaces

OPC UA (mainstream standard for industrial interoperability and information modeling)

MQTT / MQTT-SN (Lightweight publish/subscribe for cloud and edge)

AMQP, HTTP/REST, WebSocket (Common at application integration layer)

4. Process, Power, and Power Plant Communication Standards

IEC 61850 (Power systems and substation automation)

IEC 60870-5-104 (Power/Telecontrol Telemetry SCADA Protocol)

DNP3 (North American Power & Water SCADA Applications)

5. Field & Process Instrumentation Protocols

HART (Field Instrument Communication)

FOUNDATION Fieldbus (Process Control)

6. Building and Facility Management

BACnet……

7. Wireless and Narrowband Networks (Edge/Remote Monitoring)

LoRaWAN, NB-IoT, CAT (Long-range/Low-power Data Transmission Networks)

8. Operations, Monitoring, and Management Support Protocols

SNMP (Network Device Management), Syslog, SSH (Secure Operations Channel)

Note: The above list is not exhaustive but covers the most commonly encountered and prioritized protocol families in industrial projects. During project implementation, prioritize and develop a phased coverage plan based on the client’s equipment inventory.

How does industrial protocol gateway translates “the most comprehensive and extensive” into deliverable capabilities?

To ensure “protocol support isn’t just marketing hype”, we break down our work into replicable engineering practices:

1) Modular Protocol Stack (Independent Driver Modules per Protocol/Bus)

Each protocol type is implemented as a standalone driver/adapter (e.g., Modbus, S7, Profinet, EtherCAT, OPC UA, MQTT), loaded and configured dynamically at runtime.

Modularity enables rapid replacement, isolated testing, and individual upgrades, minimizing regression risks.

2) Unified Data Model & Mapping Layer (Semantic Layer)

Maps vendor-specific registers, alarm codes, and device states to standardized fields (e.g., Device.ID, Signal.Type, Value, Unit, Timestamp, Alarm.Code, Alarm.Text). Upper-layer systems consume only these standardized fields.

Supports custom mapping rules and templates (configurable mappers for legacy devices or special registers).

3) Balanced Edge Processing and Protocol Pass-Through

Perform data sampling, filtering, event extraction, alarm deduplication, and local logic processing at the gateway (reducing bandwidth and cloud-bound data volume).

Simultaneously maintains protocol pass-through capability (reporting raw frames or vendor-specific messages unchanged) to meet requirements for deep control or vendor-specific diagnostics.

4) Open SDK and Secondary Development Interfaces

Provides driver development APIs, testing tools, and examples to enable integrators or customers to rapidly add niche or custom protocols (e.g., proprietary messages for certain domestic devices).

Supports sandbox testing environments and replay tools for convenient field debugging.

5) Cloud Protocol Library and Continuous Update Mechanism

Incorporate drivers and protocol definitions into version control and an online protocol library, enabling over-the-air updates (allowing new devices or firmware to be supported without system interruption).

Regularly publish compatibility and update notes to minimize field upgrade risks.

6) Security and Compatibility Testing Process

Each driver undergoes scenario-based compatibility testing (multi-vendor parallel operation, boundary value analysis, disconnect/reconnect, concurrent access, etc.), with rollback mechanisms and log traceability provided.

Critical protocols (e.g., IEC61850, OPC UA, EtherNet/IP) receive additional security hardening and certificate management policies.

Instance Scenario: Quantifiable Benefits You Can Achieve (No exaggeration, only achievable outcomes)

Multi-brand PLCs visible and controllable on a single platform: Siemens S7, Mitsubishi MELSEC, Omron FINS, and Allen-Bradley EtherNet/IP devices can be displayed in a unified interface with consistent alarm semantics.

Minimal protocol layer modifications after field device replacement: If new devices support existing protocols (or drivers can be rapidly added via SDK), upper-layer systems require no changes.

Unified interface for maintenance personnel to view device status and alarm meanings: Consistent alarm semantics through a unified data model reduce training needs and misinterpretations.

Shortened project delivery cycles and reduced secondary development: Standardized drivers and mapping templates significantly decrease integration testing and custom development time.

Summary and Recommendations

“Supporting the most comprehensive and extensive range of PLC protocols and various industry protocols” forms the foundation of industrial protocal gateway’s capability. However, it is even more crucial to develop this capability into a maintainable, upgradeable, and reusable system. When selecting solutions, enterprises should not be swayed solely by protocol lists but should also focus on evaluating the following capabilities:

Whether drivers support online upgrades and rollbacks;

Whether driver SDKs and testing tools are provided for secondary development;

Does it feature a unified data model and configurable mapping layer?

Can edge devices perform preprocessing (filtering, alarm extraction, retransmission after network loss)?

Does it have robust compatibility and security testing processes?

IOTRouter precisely addresses these engineering details, transforming protocol compatibility into a solid bridge for enterprise cloud migration and digital transformation—rather than merely an empty list of supported protocols. If you also need to solve these challenges, try our industrial protocol gateway. It will make your work simple and efficient!