In a smart factory system, managers utilize the edge computing gateway to achieve real-time monitoring of location-dispersed devices. With the rapid development of industry, the competition for products is becoming more and more intense.

For factories, in order to ensure a competitive advantage, it is necessary to guarantee product quality and improve production efficiency. Now we offer smart factory equipment monitoring solutions that can help factories to better carry out intelligent management.

Programma Introductie

This solution directly hits a series of pain points encountered in traditional manual monitoring. It can provide real-time monitoring of online quality control equipment, allowing managers to identify and solve all types of faults that occur during operation.

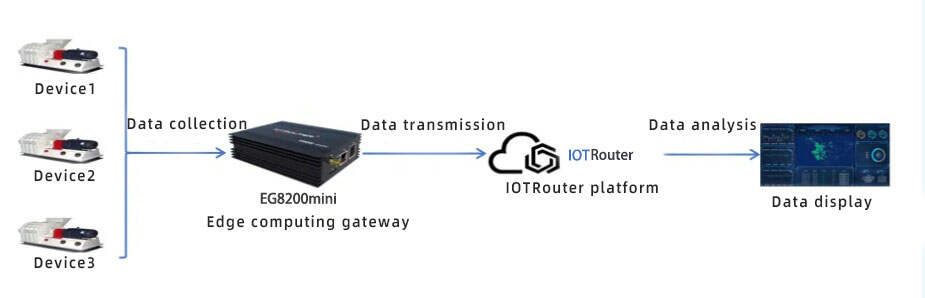

In this program, the main applied products are the EG8200mini edge computing gateway and the IOTRouter IoT platform. First of all, we need to connect the detection device with the EG8200mini edge gateway. Then we configure the relevant communication protocols and data formats to ensure that the data can be stably transmitted to the IOTRouter platform.

Oplossingsarchitectuurdiagram

Functie Introductie

1. Verzamelen en analyseren van gegevens

Utilizing the collection function of EG8200mini edge gatewayRealtime bewaking van de bedrijfsstatus van apparatuur.

Vervolgens worden de gegevens geanalyseerd via het IOTRouter-platform, dat informatie kan weergeven zoals de bedrijfsstatus van de apparatuur, storingsalarmen, belangrijke procesparameters, dosering van grondstoffen, productiehoeveelheid enzovoort.

2. Problemen oplossen

By connecting the edge computing gateway, a perfect alarm and warning system can be established. This dramatically improves the timely detection of faults and the speed of maintenance response. For example, when equipment malfunctions, the system immediately issues an alert, notifying relevant personnel to address the issue promptly, thereby reducing downtime.

3. Productkwaliteitscontrole

Using the IOTRouter platform, the collected data can be analyzed in depth to eliminate quality defects in a timely manner. This effectively realizes the process control of product quality and improves the overall quality of products. For instance, by analyzing key parameters in the production process, managers can identify factors affecting quality and make necessary adjustments.

4.Gecentraliseerd beheer

Through the intelligent monitoring system, managers can centrally compare and analyze the data situation of the equipment. This improves management efficiency and unifies the deployment of resources. For example, managers can view the operational status of all devices on a single interface, facilitating the development of optimization strategies.

5.Schaalbaarheid

The program has good scalability, allowing for function and scale expansion according to the actual needs of the factory floor. For example, we can increase the number of monitoring devices to cover more production links. At the same time, we can also incorporate other types of testing equipment into the monitoring scope for more comprehensive monitoring and management.

De waarde van oplossingen

The smart factory system solution utilizes the edge computing gateway and an IoT platform to achieve real-time monitoring of location-dispersed devices. Through the advantages of this solution, it can help customers reduce production costs, improve product quality, and achieve centralized management of equipment status.

In the future development of smart factories, edge computing and IoT technologies will further converge . Promote the intelligent upgrading of the production process. With the application of artificial intelligence and machine learning, smart factories will achieve a higher level of autonomous decision making and optimization. In addition, the widespread application of 5G networks will provide higher bandwidth and lower latency for edge computing, making real-time monitoring and data transmission more efficient. These technological advances will enable smart factories to quickly adapt to future changes and further consolidate their competitive advantage.

IOTRouter helps you to construct intelligent factories by providing accurate fault warnings, real-time data analysis, and centralized management functions. We can help you improve production efficiency and product quality, injecting new intelligence into your factory!