ET3410 RTU in water pump monitoring

Предпосылки

Industrial and mining enterprises, water supply companies, and agricultural irrigation systems possess numerous dispersed water pump stations. These stations often present the following problems: delayed fault detection, slow response times, the need for intermittent pump switching, and the requirement for 24-hour shifts for operators. Sudden pump failures can lead to production interruptions, unstable water pressure, or uneven irrigation of farmland, resulting in significant economic losses.

Требования клиента

- Сбор данных

Real-time collection of data

- Warning/Alarm

Immediate early warnings for faults and issues

- Operations/management

Техническое решение

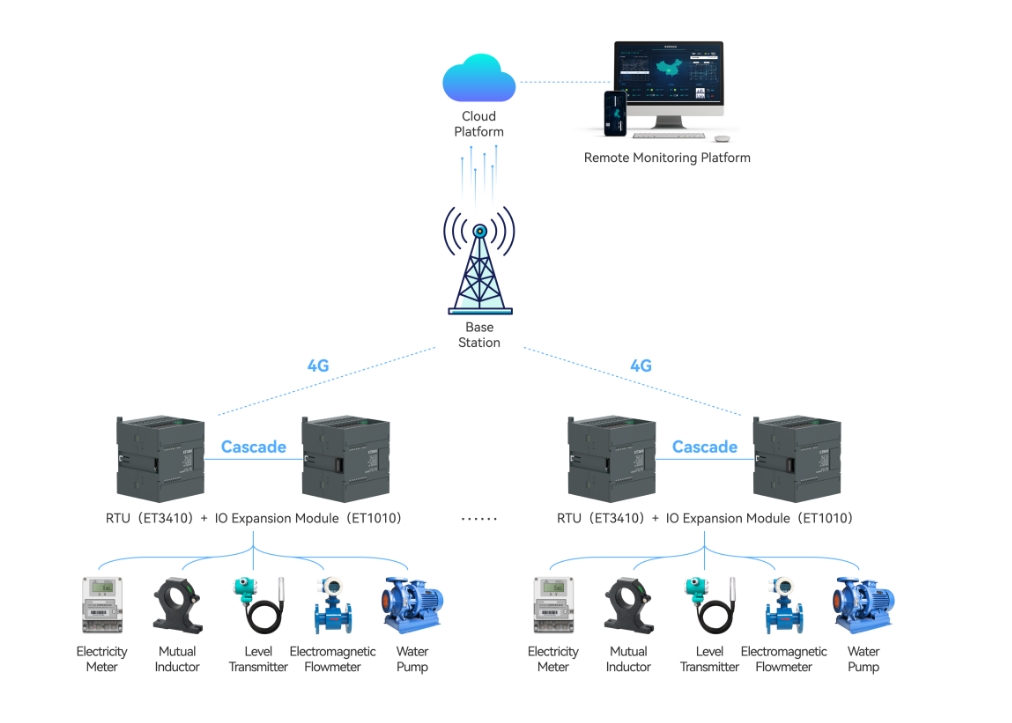

To address numerous monitoring issues in the original water pump system, a research and development company in Tangshan designed a remote water pump monitoring and management system. This system utilizes the IOTRouter ET3410 RTU as the core for data acquisition and control, connecting to the electrical components in the water pump control cabinet and integrating with the remote water pump monitoring and management system.

The ET3410 RTU periodically collects water pump status and electricity meter data. The RTU monitors whether the switch is on/off via DI (remotely monitoring the water pump's start/stop status); it connects to a three-phase smart meter via an RS-485 interface (Modbus protocol) to collect electrical parameters; and it remotely controls the water pump's start/stop via DO (digital output).

The ET3410 has built-in logic processing capabilities, allowing it to locally determine if the equipment status is abnormal and perform data preprocessing. The data is then encrypted and transmitted to the remote water pump monitoring and management cloud platform via a 4G network. The cloud platform can store, analyze, and visualize the data, and manage alarms and control policies.

Преимущества и ценность

- Flexible, Industrial-Grade Deployment

- Unmanned Operation & Efficient Maintenance

- Faster Fault Response & Reduced Downtime