Remote Monitoring for Concrete Batching Plant

Предпосылки

Commercial concrete batching plants are a critical component of the construction industry, and their production quality, efficiency, and environmental compliance are of paramount importance. Traditional batching plant management is often inefficient, leading to frequent equipment failures and production stoppages, directly impacting construction progress. Environmental protection departments are also increasingly stringent in their monitoring requirements for dust and noise pollution. Batching plant owners urgently need a system that enables comprehensive, transparent remote management of production, equipment, and environmental protection.

Требования клиента

- Сбор данных

Data needs to be collected from the batching plant's PLC control system, including: current mixing time, number of batches, volume, and actual consumption of cement/aggregate/water/admixtures. Simultaneously, data from environmental sensors (PM2.5, noise) and video monitoring signals need to be collected.

- Warning/Alarm

Alarms for mix proportion deviation, insufficient mixing time, equipment failure, and exceeding environmental standards.

- Operation/ Maintenance Management

Supports remote management via multiple terminals including computers and mobile phones, and supports remote uploading, downloading, diagnostics, and maintenance of PLC programs.

- Visual Analysis

The platform needs to display real-time production dynamics, material inventory change curves, production reports (by project, by mix proportion), and real-time environmental data dashboards.

Техническое решение

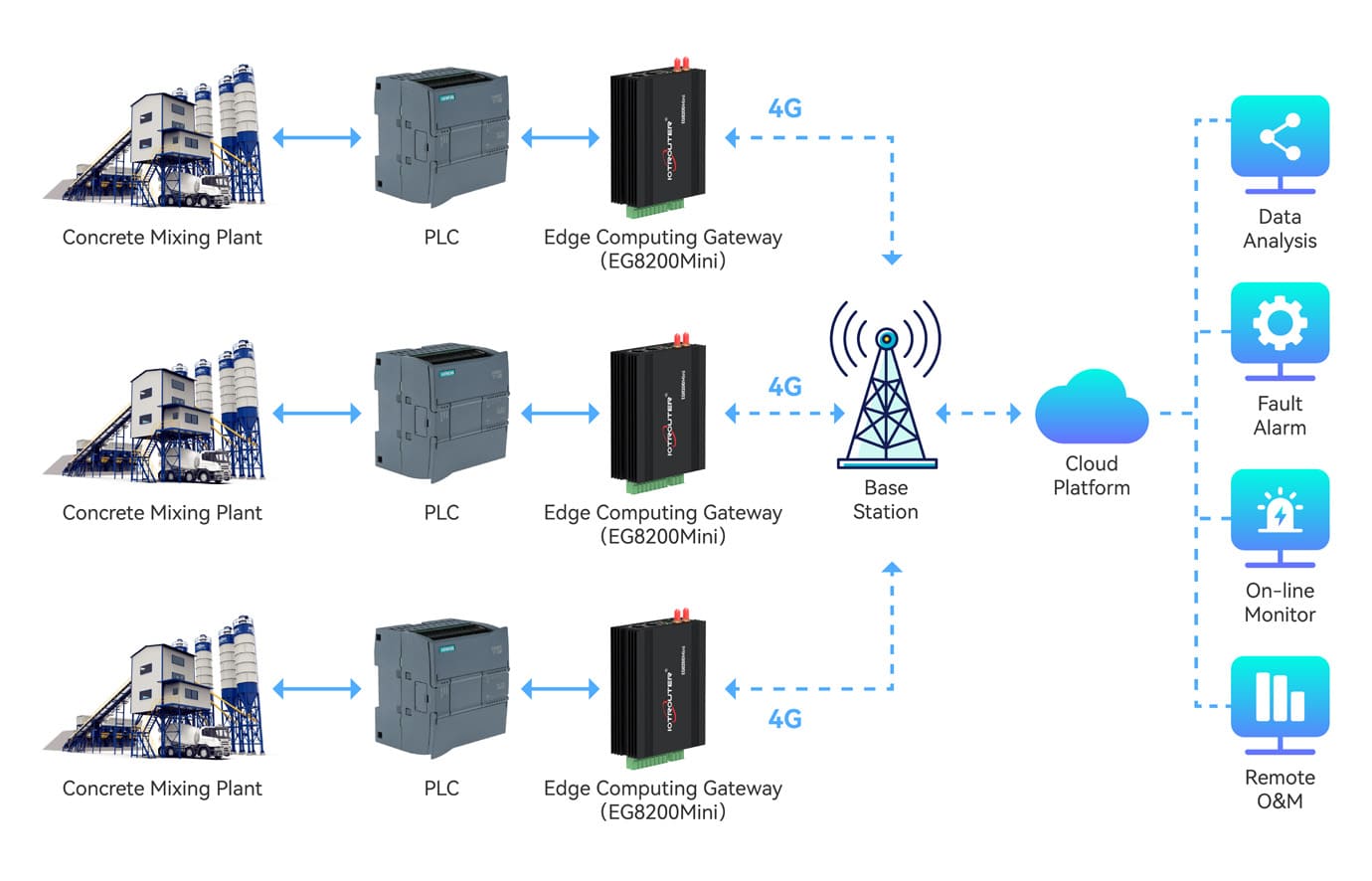

The solution utilizes 4G industrial wireless gateway (EG8200Mini) as the communication core, connecting to a dedicated cloud monitoring center platform for the mixing plant to achieve remote monitoring of the mixing plant equipment. The EG8200Mini gateway is installed in the mixing plant control room and connects to the main control PLC of the mixing plant via Ethernet or serial port. Environmental sensors and cameras are connected to the gateway via I/O or network.

Data Flow Description

1. Acquisition: The gateway reads production data from the PLC via protocols such as Modbus TCP.

2. Processing: The gateway performs data cleaning, calculations (such as cumulative volume), and determines whether limits are exceeded at the edge.

3. Transmission: All data is encrypted and transmitted to the cloud monitoring center via a 4G network.

4. Analysis: The cloud platform stores, summarizes, and analyzes the data, generating various management reports and monitoring environmental data in real time.

Functionality

1. Monitoring Dashboard Function

Real-time display of data from PLC, field controllers, sensors, etc.

2. Alarm Mechanism

Automatic early warning, multi-dimensional data analysis, alarms for non-compliant production processes such as mix ratio discrepancies, exceeding limits, etc., real-time notifications, and processing feedback records.

3. Remote Operation and Maintenance Function

Equipment manufacturer technicians can remotely configure, debug, diagnose, and update programs using the EG series remote management software. It can also easily build a virtual LAN, enabling intranet penetration, remote PLC monitoring, debugging, and program upload/download.

Преимущества и ценность

- Technical Advantages

- Business Value